Solarfun4jim

Solar seduced :-)

Looking at the spec on an 'All in one' unit, it states that maximum string voltage as 145V

It also states that MPPT in operating range 30-115v

If the open circuit voltage of my array string is 130v, what happens with the MPPT?

Does it simply ignore the voltage from 115v up to 130v or does it shut down the MPPT as an overvoltage parameter?

see unit here....

It also states that MPPT in operating range 30-115v

If the open circuit voltage of my array string is 130v, what happens with the MPPT?

Does it simply ignore the voltage from 115v up to 130v or does it shut down the MPPT as an overvoltage parameter?

see unit here....

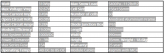

5000w 5kva 48v off Grid Solar Inverter MPPT 80a Charger Pure Sine Wave for sale online | eBay

Find many great new & used options and get the best deals for 5000w 5kva 48v off Grid Solar Inverter MPPT 80a Charger Pure Sine Wave at the best online prices at eBay! Free delivery for many products!

www.ebay.co.uk