Gr00ldude48

New Member

- Joined

- Jul 6, 2021

- Messages

- 127

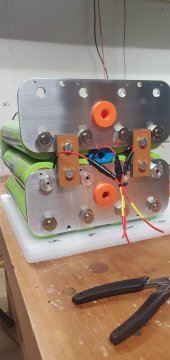

4 Batrium K9's monitoring 64 60280 cells on this 4P16S battery. First of Four batteries to build in 4 individual seismic racks. Progress pics attached.

Meanwell 12v Step down from 48v to run 4 Noctua fans relayed into batrium expansion board for heatsink cooling during bypass.

Im no expert on the batrium circuitry on the DIN Rail so if you see I need to make a modification I'd appreciate your opinions.

I also figured out how to cross reference a new 48v Shunt for a new Eaton Industrial Circuit breaker rather than doing the used ABB breaker.

Meanwell 12v Step down from 48v to run 4 Noctua fans relayed into batrium expansion board for heatsink cooling during bypass.

Im no expert on the batrium circuitry on the DIN Rail so if you see I need to make a modification I'd appreciate your opinions.

I also figured out how to cross reference a new 48v Shunt for a new Eaton Industrial Circuit breaker rather than doing the used ABB breaker.