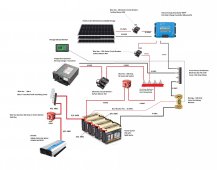

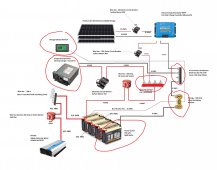

I have been researching and planning my first DIY and would appreciate any suggestions. Especially the fuse and fuse location!!! And wire sizes. I may only end up with two Power Queen 12v 190Ah's but four is the max for sure.

BTW, I used someone on DIY schematic, and just replaced and moved the parts around that I wanted (the title was 2000-watt inverter schematic), so thank you very much, it really helped to be able to see it. If it looks familiar, it is! Thanks!

BTW, I used someone on DIY schematic, and just replaced and moved the parts around that I wanted (the title was 2000-watt inverter schematic), so thank you very much, it really helped to be able to see it. If it looks familiar, it is! Thanks!