@ArkRob Sure. So the rails that the panels are attached to are 10' sections of superstrut.

I used regular flat brackets to connect to struts together:

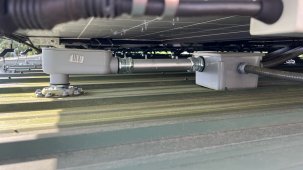

The panels are attached via cone nuts and stainless 1/4" bolts with insulated washers on the panel side:

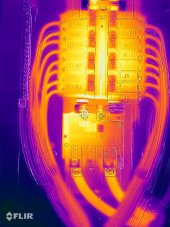

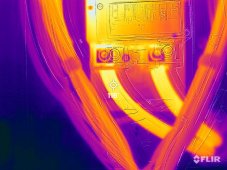

The rails of superstrut are bonded together and run into the ground on the inverters.

And I have East, West and South bracing on the tall side:

As has been pointed out earlier, I might have issues with rot at the base of the 6x6 posts being set directly in cement like they are.

I used 3/8" backer rod between the panels and siliconed the gaps as I installed the panels. I get a few drips during heavy rain, but it has held up well over the last 2 years since I installed it.

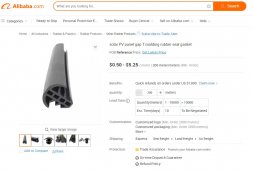

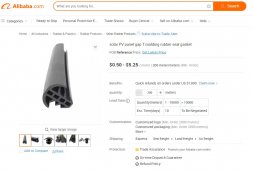

If I do any more pole barns like this, I would see if I could locate something like this to seal the gaps:

I don't need 200 meters of the stuff, which is the minimum order quantity from Alibaba. If anyone knows a good source for that molding, I'm all ears.

Let me know if you have any other questions and I'll be happy to try to answer them.

I used regular flat brackets to connect to struts together:

The panels are attached via cone nuts and stainless 1/4" bolts with insulated washers on the panel side:

The rails of superstrut are bonded together and run into the ground on the inverters.

And I have East, West and South bracing on the tall side:

As has been pointed out earlier, I might have issues with rot at the base of the 6x6 posts being set directly in cement like they are.

I used 3/8" backer rod between the panels and siliconed the gaps as I installed the panels. I get a few drips during heavy rain, but it has held up well over the last 2 years since I installed it.

If I do any more pole barns like this, I would see if I could locate something like this to seal the gaps:

I don't need 200 meters of the stuff, which is the minimum order quantity from Alibaba. If anyone knows a good source for that molding, I'm all ears.

Let me know if you have any other questions and I'll be happy to try to answer them.

Last edited: