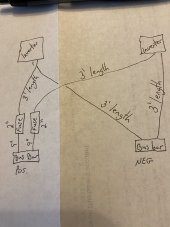

Have read the battery cable lengths must be the same on POS and NEG otherwise it effects the volts. I am installing two LV6548 inverters for two phase, all battery lengths equal but I forgot to account for a fuse (125 amp) in the POS cable from buss bar to inverter which is approx. 4" long and will have to add a short length of cable in order to use the fuse box. Questions:

1. Will this extra length on the POS cable be enough to make a difference on the volts?

2. Using a rack (5) of SOK 48v batteries each with a breaker, so is it necessary to have a fuse inline from the buss bar to inverter?

Beginner here, so taking it slow and trying to do it right.

Thank you,

zack

1. Will this extra length on the POS cable be enough to make a difference on the volts?

2. Using a rack (5) of SOK 48v batteries each with a breaker, so is it necessary to have a fuse inline from the buss bar to inverter?

Beginner here, so taking it slow and trying to do it right.

Thank you,

zack