Bruxollini

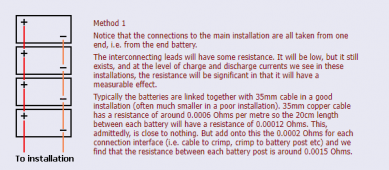

New Member

- Joined

- Jul 18, 2022

- Messages

- 15

I have a 5- battery system with eg-4 lifepo2 installed on signature solar rack, connected with 1awg cable to Schneider XW+ 6848. Tonight as the water heater was running and pulling 4.5kwh from the battery system, the positive cable overheated and started smoking. This is the first time this happened and we’ve run said water heater at night without any problems multiple times. Wire temp comes down after I shut off the water heater and there’s only a small load running. No alarms on the batteries or the inverter. Any points as to what is causing this and maybe how to possibly fix it? TIA