BillCaswell

New Member

- Joined

- Jan 10, 2020

- Messages

- 78

I found this today from the Blue Sea web site:

”Corroded connections are the main cause of high resistance connections that cause equipment to quit working or to work poorly. Frequently high resistance connections are the result of corrosion on the surface of unplated brass and copper conductors. Of the common plating materials used in electrical applications Nickel (Ni), Gold (Au), Tin (Sn) and Silver (Ag), tin is the best choice for marine electrical applications.

Although tin does corrode (oxidize), the tin oxide layer is a thin brittle layer and the tin is very ductile. When two tin plated surfaces are mated under pressure the brittle surface layer of tin oxide will crack and displace allowing the lower pure tin layers to cold weld, forming An airtight bond that inhibits further oxidation in the connection.

Tin is, interestingly, not a particularly good conductor, but since the thickness of the plating is usually only about .0005", the distance the current travels is very short and therefore not high in resistance.”

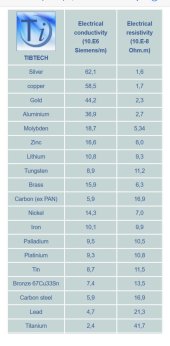

I was confused because of this chart which shows the conductivity/resistance of tin compared to copper. I plan to use tinned copper wire, lugs and bus bars. But am curious about mixing nickel plated bus bars with tinned wire and lugs?

”Corroded connections are the main cause of high resistance connections that cause equipment to quit working or to work poorly. Frequently high resistance connections are the result of corrosion on the surface of unplated brass and copper conductors. Of the common plating materials used in electrical applications Nickel (Ni), Gold (Au), Tin (Sn) and Silver (Ag), tin is the best choice for marine electrical applications.

Although tin does corrode (oxidize), the tin oxide layer is a thin brittle layer and the tin is very ductile. When two tin plated surfaces are mated under pressure the brittle surface layer of tin oxide will crack and displace allowing the lower pure tin layers to cold weld, forming An airtight bond that inhibits further oxidation in the connection.

Tin is, interestingly, not a particularly good conductor, but since the thickness of the plating is usually only about .0005", the distance the current travels is very short and therefore not high in resistance.”

I was confused because of this chart which shows the conductivity/resistance of tin compared to copper. I plan to use tinned copper wire, lugs and bus bars. But am curious about mixing nickel plated bus bars with tinned wire and lugs?