energyhunter

New Member

- Joined

- Feb 20, 2022

- Messages

- 83

Appreciate any input. I'm upgrading to EG4 6000XP inverters and I need additional length for 8 connections of 10 AWG PV wire that is already indoors, to reach the new inverter connections.

Wouldn't tin plated copper butt splice connectors fit the bill for this use indoors? Seems like outdoor exposure arguments against wouldn't apply......even less when using marine grade multi wall adhesive lined heat shrink tubing with air/water tight seal....Rated to 600v.

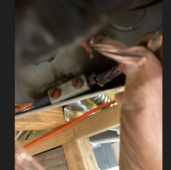

This is what I'm looking at possibly using instead of MC4 connectors to slightly lengthen the indoor part of my PV wire:

Wouldn't tin plated copper butt splice connectors fit the bill for this use indoors? Seems like outdoor exposure arguments against wouldn't apply......even less when using marine grade multi wall adhesive lined heat shrink tubing with air/water tight seal....Rated to 600v.

This is what I'm looking at possibly using instead of MC4 connectors to slightly lengthen the indoor part of my PV wire:

Butt Splice Connector Pure Copper Tin-Coated Marine Grade Uninsulated

Create your cable connections with WindyNation's pure copper butt connectors. Perfect for RV's, boats, cars, trucks, cars, campers, ATV's, golf carts and a variety of applications where heavy duty battery cables, marine cables, or welding cables need to be spliced together! Insert spliced cables...

www.windynation.com