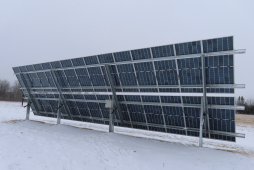

Just in time for these relentless cloudy days. Producing about 800W at 10:30AM local time with this solid cloud cover.. enough to actually start charging battery bank again which is now at 37%.

30 480W Q.PEAK DUO XL-G10 on Sinclair mount. Connected to a EG4 18kPV which is only being used as solar charge controller currently. Two strings of 6 and two strings of nine paralleled together. There are four other older arrays totaling less then 9kW.

30 480W Q.PEAK DUO XL-G10 on Sinclair mount. Connected to a EG4 18kPV which is only being used as solar charge controller currently. Two strings of 6 and two strings of nine paralleled together. There are four other older arrays totaling less then 9kW.