sabo

New Member

I have 20 250 watt used panels from San Tan

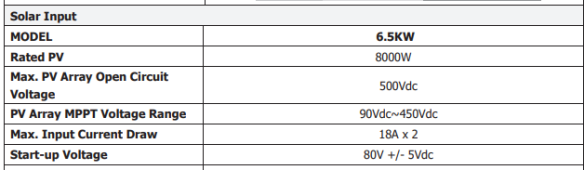

I am considering the EG4 6.5 KW 48 Volt ( 1 to start another in 6 months )

signaturesolar.com

signaturesolar.com

I am concerned about the Voltage Loss. Im very new to solar. I have read some forum posts on a few forums. There was some debate between running Solar Cable and AWG. So far it sounds like it is best to use Solar Cable from the panels 230 ft to the inverter. Input requested on these statements. Also input on the number of panels to run in series is requested.

Are all Solar cables the same thickness or do I need to buy a specific size for this run?

Is the fan noise on the newer EG4 6.5 Kw inverters still excessive?

I have a solar combiner box. I can use this if needed.

I am considering the EG4 6.5 KW 48 Volt ( 1 to start another in 6 months )

EG4 6000XP Off-Grid Inverter | 8000W PV Input | 6000W Output | 480V VOC Input | 48V 120/240V Split Phase | All-In-One Solar Inverter

The EG4 6000XP is a cutting-edge 48V split-phase, off-grid inverter and charger, designed to revolutionize your energy needs. With an impressive 8kW of PV input capacity and an efficient 6kW continuous power output, it also serves as a battery 140A charger. What sets it apart is its scalability...

signaturesolar.com

signaturesolar.com

I am concerned about the Voltage Loss. Im very new to solar. I have read some forum posts on a few forums. There was some debate between running Solar Cable and AWG. So far it sounds like it is best to use Solar Cable from the panels 230 ft to the inverter. Input requested on these statements. Also input on the number of panels to run in series is requested.

Are all Solar cables the same thickness or do I need to buy a specific size for this run?

Is the fan noise on the newer EG4 6.5 Kw inverters still excessive?

I have a solar combiner box. I can use this if needed.

Last edited: