hwse

Solar Enthusiast

- Joined

- Jan 2, 2021

- Messages

- 585

Well, I am committed. dreaming, plotting, planning no more. Let the building begin.

I finally did it. My LFP is on its way.

I finally did it. My LFP is on its way.

- (

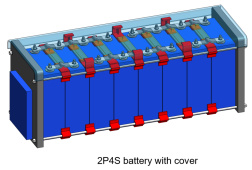

EVE 280K (560A @ 12v) From Docan Power

- 4s JK BMS with 2-amp active balance and 200-A charge/discharge capacity (350-A surge for 5 minutes) from Henkzor

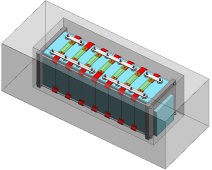

- Flexible milti-thin plate buss bars for 2p4s configuration

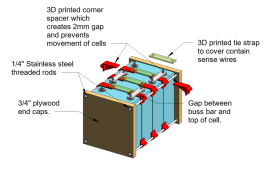

- 3d printed corner pieces to create 1mm space and secure the four corners form moving.

- The bits and bobs to create the "a simple diy alternator charge system for lifepo4 batteries (12v system) on boats" from Wout Beekhuizen.

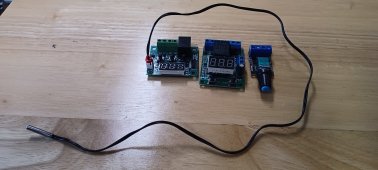

- PWM controller to limit output

- Voltage switch to turn on and off as needed.

- Thermostat to shut down alternator if it gets too hot.