Am attempting to add images to helpfully better show what I'm up against.

With Inside Wall, that is all the real estate I have to work with inside. While the inspector was willing to talk with me he said putting the inverter there was ok. Grid wire comes in from under slab and into ATS (all inside wall cavity). ATS then has wire run to main panel. Current generator wiring comes in through ICF wall and lands on left hand side of ATS inside of the wall.

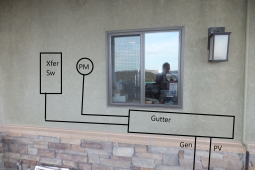

With Outside Wall, some variation on this is all I can come up with to work. I would prefer to not put the 15k out there cause early morning sun would fry the display.

With Array 2, this is looking north. The last two years we have had occurrences of severe winds. Code says 120 mph and 30 psf snow load. I just lose 15 minutes of sun by not putting array on top of knoll. I like a little bit of wind protection by coming down on slope a bit. All there are clouds out there, if you look closely, one of those humps way out there is Pikes Peak.

PV Conduit Run - that is a straight shot just to the east (right) of the leach field.

Last pic is close to looking directly south. Behind the house is the terrain that causes quit a bit of shading in the late afternoon in the winter. Our latitude here is 40 deg. I don't have any flat or close to flat terrain where I can otherwise put the array and still get reasonable sun exposure

If anyone sees something that makes this impossible to do from a big picture, just say so.

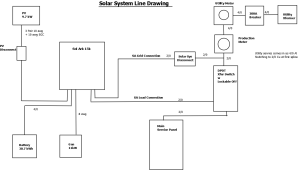

I'll noodle on doing a line diagram, but I think that will just be to much of a simplification.

Thanks for input.

With Inside Wall, that is all the real estate I have to work with inside. While the inspector was willing to talk with me he said putting the inverter there was ok. Grid wire comes in from under slab and into ATS (all inside wall cavity). ATS then has wire run to main panel. Current generator wiring comes in through ICF wall and lands on left hand side of ATS inside of the wall.

With Outside Wall, some variation on this is all I can come up with to work. I would prefer to not put the 15k out there cause early morning sun would fry the display.

With Array 2, this is looking north. The last two years we have had occurrences of severe winds. Code says 120 mph and 30 psf snow load. I just lose 15 minutes of sun by not putting array on top of knoll. I like a little bit of wind protection by coming down on slope a bit. All there are clouds out there, if you look closely, one of those humps way out there is Pikes Peak.

PV Conduit Run - that is a straight shot just to the east (right) of the leach field.

Last pic is close to looking directly south. Behind the house is the terrain that causes quit a bit of shading in the late afternoon in the winter. Our latitude here is 40 deg. I don't have any flat or close to flat terrain where I can otherwise put the array and still get reasonable sun exposure

If anyone sees something that makes this impossible to do from a big picture, just say so.

I'll noodle on doing a line diagram, but I think that will just be to much of a simplification.

Thanks for input.