MrM1

I'm Here, But I'm Not All There

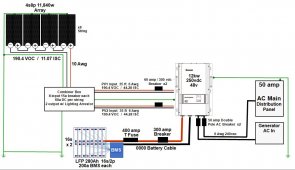

I'm old, It's Late, it's 1am and I am looking at the monitor with just one eye. Can you please talk a look at this wiring, fuse, breakers, ground etc diagram and give me some pointers? What have I missed?

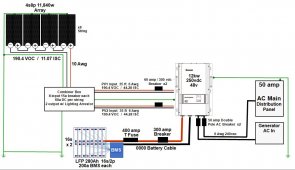

I have not ordered any balance of system yet, just main components. So just now getting it planned out. This will be a fully Off-Grid dwelling and work barn. Installing a Growatt SPF 12kv DVM 250vdc inverter and over paneling with a 11,840w array 4s8p. The 8 series strings will join into a double combiner box that will run 2 PV inputs to the inverter. Each will be the parallel of 4 of the 8s strings. So PV1 will get 4s4p and PV2 will get 4s4p.

Plan is to house the Inverter, Main AC Distribution, Switchgear and Batteries in the solar shed. This will be within 20 ft of the Array. But if closer I could combine / tie all grounds together.

Please take a look to see if I missed anything or if anything looks out of balance. The PV breakers for the 2 PV in runs from the combiner are just going to be used as switches to turn the array off from inside the shed.

Trying to say as close to NEC 2017 as possible, But ...

- Do I need 4/0 for the battery cable?

- Are all other wires sized correctly for potential loads?

- Do I need #6 from the combiner? And to the main AC distribution?

Thanks in advance.

Mike

I have not ordered any balance of system yet, just main components. So just now getting it planned out. This will be a fully Off-Grid dwelling and work barn. Installing a Growatt SPF 12kv DVM 250vdc inverter and over paneling with a 11,840w array 4s8p. The 8 series strings will join into a double combiner box that will run 2 PV inputs to the inverter. Each will be the parallel of 4 of the 8s strings. So PV1 will get 4s4p and PV2 will get 4s4p.

Plan is to house the Inverter, Main AC Distribution, Switchgear and Batteries in the solar shed. This will be within 20 ft of the Array. But if closer I could combine / tie all grounds together.

Please take a look to see if I missed anything or if anything looks out of balance. The PV breakers for the 2 PV in runs from the combiner are just going to be used as switches to turn the array off from inside the shed.

Trying to say as close to NEC 2017 as possible, But ...

- Do I need 4/0 for the battery cable?

- Are all other wires sized correctly for potential loads?

- Do I need #6 from the combiner? And to the main AC distribution?

Thanks in advance.

Mike

Last edited: