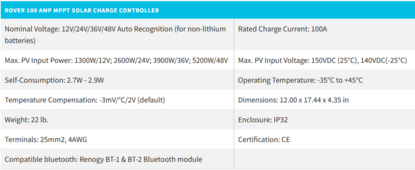

Just to be very clear first, is this your charge controller?

View attachment 205301

I don't want to give you the wrong advice based on the wrong electronics? With a limit of 150V, there is not a very good reason not to put 5 panels in series to make 5A 100V DC panel strings. I would however stop buying 12V panels completely. At 1W/$ they are grossly overpriced. Purchase larger, high-voltage residential panels instead. They may be commonly referred to as "grid-tie panels". Shop locally for those instead of mail-order. Shipping is the killer in solar panel pricing. With cash and carry purchases, you should be getting new panels for 2-3W/$. Maybe 4-5W/$ for used panels.

Renogy does not market the best stuff. Used quality panels I purchased off of Craigslist outperformed new Renogy panels. I am not impressed with their batteries either. With six of them, you are kind of stuck? As a general rule, the more parallel strings of batteries you have, the more poorly balanced they become. You could make a 24V system, with 3 parallel strings, but I think even 3 is too many, but of course not as bad as six. You could make a 48V system with four of them in series, but you are stuck with two extra batteries. One alternative is to buy two more of those batteries and make a 4S2P battery bank. However, I loathe the thought of recommending the purchase of more Renogy batteries. So, maybe a 3S2P 24V system is the best alternative you have.

If you want to buy more panels, first remember the two following mantras.

1) In series volts add, while amps stay the same. In parallel amps add, while volts stay the same.

2) When mixing panels in a series string, any voltage can be paired but amperage must be within 5%. When mixing panels in different parallel strings, any amperage can be paired, but voltage must be within 5%.

If you want to buy additional panels in the future, and you already have five 20V panels wired in series for 100VDC, all you need to do is match any other panel string to the same voltage (mantra 2, sentence 2). Shop for 60-cell grid-tie panels with a Vmp of ~33V. Three of those in series would give you the 99-100VDC to match up with the strings you already have. Actually, any voltage between 95-105V is going to be perfectly fine.

Then replace the 12V inverter with a 24V one. There are better choices then Renogy. What kinds of loads will you need to support. Lights, TV, computer, and a frig is easy. Big power tools, or anything with a big electric motor that starts under load has what's called a "starting surge", which is typically 3-5X the documented power draw, for just 500 milliseconds or so.

Read the fine print of the inverter you chose to buy. Ignore how MUCH they can surge. Pay close attention to how LONG they can surge. The cheaper high-frequency transformerless inverters typically can surge for less than 1 AC cycle, or <16 milliseconds. Quality transformer-based inverters can surge for between 5-60 seconds (not milliseconds), and are perfect for big power tools.

For my workshop, I power that with Schneider's Conext 4024 inverter. I've run a cement mixer, 1.6hp air-compressor, and a 7" saw, all at the same time, without the inverter blinking! It does however cost 3X the price of lessor inverters, but it can run 3X more stuff. You get what you pay for! It also puts out split-phase 120/240VAC, and has a built-in generator charging circuit.