Benjammann

New Member

- Joined

- Apr 26, 2021

- Messages

- 8

My wife and I are mostly finished converting an 8.5' x 20' enclosed trailer into a concessions trailer. Since the beginning we've been very interested in some sort of solar / battery powered system but resorted to a 12,000W generator due to not having the budget for a full solar system. As we get closer to launch I've been seeing you guys build with these inexpensive lithium batteries ordered overseas and it has made me realize we could possibly scratch something together sooner than later.

So right now we have a full 50A RV style system installed, although there is regrettably zero DC right now, aside from a 12V water pump run off a little transformer block plugged into 120V.

The idea right now is to not do solar yet, as we only have room for about 13-16 panels, and they would all have to be 400W to stand a chance of satisfying our power needs. What I'm thinking of starting with is building up a bank of lithium batteries that at first would just supplement the generator (likely with a victron multiplus II), allowing us to use a smaller quieter one, and then possibly replacing it all together. Current rough estimate of power consumption per day is around 20,000WH or around 6,000W max load.

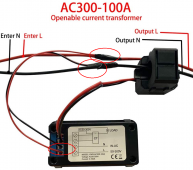

This brings me to my first question for you guys. I'm trying to get a more accurate reading on power consumption since a lot of the equipment either cycles on and off by itself, such as fridge and freezer, hot water, etc. and some gets cycled manually like blenders, food processors, water pump, and then some cycled manually but likely have different levels of consumption than just what is listed (things like pressure cookers and expresso machines) So it's difficult to calculate. Thus, I'm looking to install one of these power meters on the AC panel so I can know without a doubt what we are looking at.

Wondering if anyone had experience with these on 50 amp systems. I think the deal is that the two 120V lines have been run into either side of the panel. I read something in a review for a similar product that in order to hook one of these up to a system with two 120V lines, you ignore the neutral, and you wire in the hot line from each side into the device. Does anyone have experience here with this?

Thanks for taking a look, and I hope to grow here to be able to help others in the future, as I am sure it's going to take a lot of help from others for me to get going.

Thanks again,

Ben

So right now we have a full 50A RV style system installed, although there is regrettably zero DC right now, aside from a 12V water pump run off a little transformer block plugged into 120V.

The idea right now is to not do solar yet, as we only have room for about 13-16 panels, and they would all have to be 400W to stand a chance of satisfying our power needs. What I'm thinking of starting with is building up a bank of lithium batteries that at first would just supplement the generator (likely with a victron multiplus II), allowing us to use a smaller quieter one, and then possibly replacing it all together. Current rough estimate of power consumption per day is around 20,000WH or around 6,000W max load.

This brings me to my first question for you guys. I'm trying to get a more accurate reading on power consumption since a lot of the equipment either cycles on and off by itself, such as fridge and freezer, hot water, etc. and some gets cycled manually like blenders, food processors, water pump, and then some cycled manually but likely have different levels of consumption than just what is listed (things like pressure cookers and expresso machines) So it's difficult to calculate. Thus, I'm looking to install one of these power meters on the AC panel so I can know without a doubt what we are looking at.

Wondering if anyone had experience with these on 50 amp systems. I think the deal is that the two 120V lines have been run into either side of the panel. I read something in a review for a similar product that in order to hook one of these up to a system with two 120V lines, you ignore the neutral, and you wire in the hot line from each side into the device. Does anyone have experience here with this?

Thanks for taking a look, and I hope to grow here to be able to help others in the future, as I am sure it's going to take a lot of help from others for me to get going.

Thanks again,

Ben