AlaskanNoob

Solar Enthusiast

- Joined

- Feb 20, 2021

- Messages

- 906

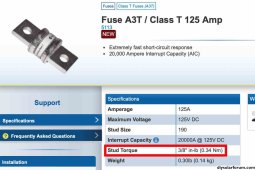

I'm trying to put my t-fuses in the t-fuse holder and if I'm reading this spec sheet correctly, I'm supposed to only torque the t-fuse to .34NM? My torque wrench min torque is 60 inch pounds, so if this is really the number I'm going to have to figure something out. That number seems so low. Seems to be finger tight which just seems odd, but I have no experience with such things.

www.bluesea.com

www.bluesea.com

Fuse A3T / Class T 125 Amp - Blue Sea Systems

Use with Class T Fuse Blocks for circuit protection of devices including inverters. high interrupt capacity for large battery banks including Lithium-ion and TPPL batteries.

| Stud Torque | 3/8" in-lb (0.34 Nm) |

Last edited: