googdot

New Member

Do both the P- and B- cables coming from either side of the BMS (JK-B2A8S20P) in an 8S config need to be the same length?

Last edited:

Thanks for the reply Rich - appreciated.

Now the balance wires, there is a different story.

To be neat and tidy or keep them all the same length ???

I personally keep them the same length AND solder them to the ring terminal.

I try to tidy them up, give up and then put the lid on !!!

Well, they also draw current when the BMS equalizes the cells. But I assume that the BMS first senses and then later it starts to draw current to equalize. So cable length shouldn't matter.No need for equal length, they only sense voltage and wire length doesn't effect the readings as such low currents.

What do you base that on? Where did you find that information?You are dealing with mV, same length and soldered unless you have an industrial crimper and know how to use it.

I mean the same length part. That the cables have to be the same length. Where is that specified?It is just a fact.

High-end industrial and military prefer crimps for a reason I would have to look up but they are using thousands of dollars worth of equipment and crimps. On the DIY cheap end of the scale hopefully you can spot a good solder joint from a bad one and do it for less than 20 bucks.

I'd say it depends on the BMS and its balancing algorithm, so you need to check with the manufacturer before each installation.It's not, it's just my OCD for electrical rather than neatness.

My first battery build (trolling battery) was problematic at first because of a balance lead crimp. I used insulated terminals and a Kline crimper. Despite folding over the wire to get a better barrel fill and a two handed death grip on the crimper there were loose connections. Now on the small stuff, I only use non insulated terminals, a crimper that folds and small dab of solder to plug the open end because the heat shrink can’t quite seal the deal. Yeah I know OCD, but nothing to chance.It is just a fact.

High-end industrial and military prefer crimps for a reason I would have to look up but they are using thousands of dollars worth of equipment and crimps. On the DIY cheap end of the scale hopefully you can spot a good solder joint from a bad one and do it for less than 20 bucks.

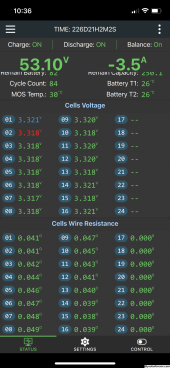

One of the first things that a JK does at power up is look at the resistance(pictured) of each of the balance leads and most likely take account for it. Four JK’s and and all have a harness with wire just long enough to do the job, stay out of harm’s way and look neat. Very often they finish absorb with a delta of nil so for this brand balance lead length isn’t too important.

I can’t speak for other brands of BMS.

View attachment 172357

Very often they finish absorb with a delta of nil

one of my biggest questions with the DALY units...with 16s it makes for extending the cables or else...I looked at the nice and tidy vs resistance. Granted the voltages being discussed are not big. Considering that I will probably be the only one who knows the wires are the same length I tucked the Bms behind the batteries and my next one will be inside a metal battery case. I utilized the same length. Perhaps a personal preference vs a hard fast rule but adds to the consistency of the build.

All four (3 bats in one system) are usually under .003 delta before the inverter releases absorb (20-45 minutes) and goes to float. I don’t charge any higher than 3.45 volts per cell. 300ah cells, jk is 2 amp balance. All are open loop (no inverter/battery network). MPP LV6548 built in Lifepo4 algorithm in “User” settings.That JK gives some nice data respecting wire resistance that my JB does not. Nice!

What delta do you see you when the cells are in the knee area of the charge curve, say 3.50v and above?