ohthetrees

New Member

- Joined

- Jun 28, 2021

- Messages

- 76

Thought someone might be interested...

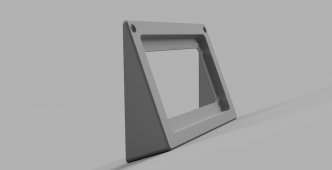

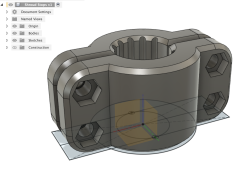

I installed a GX touch (cerbo) in my boat. I really like the system, but the viewing angle of the display is poor, and touching the screen was awkward with where I had it mounted. It looks washed out when looking from slightly above. I designed and 3d printed a mount that 1) filled a pre-existing cutout in my panel and 2) angled the display so that I can see it much better. Here are a couple of pics. Tried to attach the STL in case someone wants to print their own, but the forum software won't allow it. If someone wants the STL, let me know, and I'll figure out how to get it to you.

I installed a GX touch (cerbo) in my boat. I really like the system, but the viewing angle of the display is poor, and touching the screen was awkward with where I had it mounted. It looks washed out when looking from slightly above. I designed and 3d printed a mount that 1) filled a pre-existing cutout in my panel and 2) angled the display so that I can see it much better. Here are a couple of pics. Tried to attach the STL in case someone wants to print their own, but the forum software won't allow it. If someone wants the STL, let me know, and I'll figure out how to get it to you.