sajjen

New Member

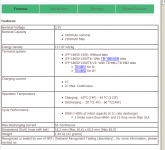

We have several sheets here at work for multiple LiFePO4 batteries and virtually all of them state that the INDUSTRY STANDARD allowable charge rate at –10°C (14°F) is 0.02C. At this low current, the charge time would stretch to over 50 hours.

BUT as i stated earlier -- At 0°C (32°F), the pack appears to be charging normally, however plating of metallic lithium usually occurs on the anode during a sub-freezing charge. This is permanent and cannot be removed with cycling. Also batteries with lithium plating are more vulnerable to failure if exposed to vibration or other stressful conditions. The worse thing you can do to a very cold LiFePO4 battery is move it around or shake it …

I'm not arguing about the fact that plating will occur if you charge at too high a rate at too low a temperature. It's a known fact, and very harmful to the cells and the damage is indeed permanent.

It is not as simple as any charge below freezing = death and any charge above freezing = fine. From a basic chemistry viewpoint, the charge rate that can be accepted is a function of the temperature. Plating can occur at high temperatures if the charge rate is high enough. Plating at low temperatures can be avoided if the charge rate is low enough.

I've also seen many cell data sheets through my work. Most of them are copies of each other. None of them have very detailed testing data.