John Frum

Tell me your problems

- Joined

- Nov 30, 2019

- Messages

- 15,230

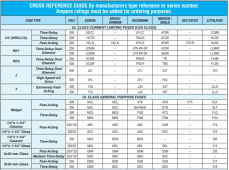

The BMS should trip on short circuit current in microseconds.These days, fuses are also specifically useful to protect semiconductors (google "semiconductor fuse"). With a fast acting fuse, your BMS will likely survive (I tested this). With a slower fuse, your wires will be fine, but you will likely fry the BMS. Keep in mind that short circuit current with a BMS that starts to smoke/burn might be much lower than a direct short on the battery terminals outside the BMS. LiFePO4 by the way also has a more limited short circuit current compared to e.g. LiPo or other chemistries.

The semiconductor fuse should blow in milliseconds.

Therefore if the semi fuse blows it means the BMS has already failed.

The question I have is, will the really fast blow fuses prevent the already failed BMS from causing a fire?

Last edited: