You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Composite rooftop racking recommendation?

- Thread starter AlpineJoe

- Start date

SnapNrack's top speed system: https://snapnrack.com/products/topspeed-mounting-system/ If your wind and snow load are within it's capabilities. Also doesn't have long rails that can be expensive to ship.

AlpineJoe

Solar Enthusiast

- Joined

- Jun 13, 2022

- Messages

- 213

Wow, that’s a lot of pieces and penetrations. Maybe I’ll look into aluminum channel and take a driving trip to a metal place for will call pickup.SnapNrack's top speed system: https://snapnrack.com/products/topspeed-mounting-system/ If your wind and snow load are within it's capabilities. Also doesn't have long rails that can be expensive

Q-Dog

¯\_(ツ)_/¯

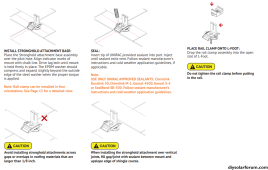

Tamarack has roofmount kits to mount 4 and 8 panels. They also have 2 panel add on kits if you want to mount 6 or 10 panels.

tamaracksolar.com

tamaracksolar.com

Roof Mounting System | Tamarack Solar Products

SIMPLE AND ECONOMICAL Flush Mount (FM) Roof Mount System Offering the first major improvement in railed system technology in many years. Single tool installation is straightforward and extremely intuitive. The two rail profiled (heights) available to meet various snow and wind ratings. Rails...

tamaracksolar.com

tamaracksolar.com

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,182

I've picked up Unirac Standoffs and rails I plan to install, with flashing.

My array will be 24, 325W REC on two faces, similar of another brand on other.

My array will be 24, 325W REC on two faces, similar of another brand on other.

zanydroid

Solar Wizard

What are the pros/cons of UniRac Standoff vs Flashkit Pro?

It looks like Standoff uses generic standard-issue galvanized flashing with EPDM boot.

It looks like Standoff uses generic standard-issue galvanized flashing with EPDM boot.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,182

I like the idea of flashing, should be long lasting.

2-piece standoff is the only way to install them retrofit.

Other designs I see, including from Unirac, are just a lag screw through the shingles. Both companies probably have comparable product lines.

Something about a way to pump it full of sealant, or comes with sealant inside. Call me old fashioned ... if that was good enough we would just cut a hole for vent pipes and caulk around it.

Speed is obviously the advantage.

San Jose does not require structural design if no more than 40 lbs per attachment point. Other cities have similar numbers. Similar in Oakland, but they do want a drawing of roof trusses.

I think that is allowing lag screws into sheathing. I intend to hit rafters.

My own place, going to take my time and do the best I can.

2-piece standoff is the only way to install them retrofit.

Other designs I see, including from Unirac, are just a lag screw through the shingles. Both companies probably have comparable product lines.

Something about a way to pump it full of sealant, or comes with sealant inside. Call me old fashioned ... if that was good enough we would just cut a hole for vent pipes and caulk around it.

Speed is obviously the advantage.

San Jose does not require structural design if no more than 40 lbs per attachment point. Other cities have similar numbers. Similar in Oakland, but they do want a drawing of roof trusses.

I think that is allowing lag screws into sheathing. I intend to hit rafters.

My own place, going to take my time and do the best I can.

zanydroid

Solar Wizard

I like the idea of flashing, should be long lasting.

2-piece standoff is the only way to install them retrofit.

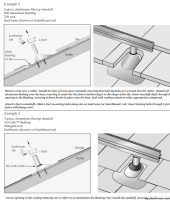

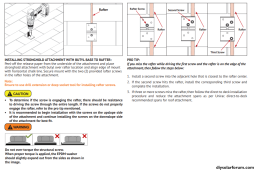

The Flashkit Pro is what I used. Pictures comparing both below.

My understanding is. The Flashkit Pro achieves sealing basically around the lag bolt. You put glue into the hole, and the bolt + foot each have EPDM (two washers that line up with each other) around the bolt.

While the Standoff is very similar to a plumbing vent, service entry mast, or conduit entry. Looks like you can pick whatever kind of flashing you want.

Other designs I see, including from Unirac, are just a lag screw through the shingles. Both companies probably have comparable product lines.

Something about a way to pump it full of sealant, or comes with sealant inside. Call me old fashioned ... if that was good enough we would just cut a hole for vent pipes and caulk around it.

Here are two flashing free options from Unirac. First one comes with Butyl sticky stuff on the bottom, second one uses injection port. You have to be a lot more precise than with flashing.

These things are supposed to be faster though b/c there is zero cutting of shingles. However you have to be pretty precise at finding the rafters.

UniRac and couple other companies also sell through-roof junction boxes with the same no-cut + injection idea, with minimal flashing. That might be a little safer to use since junction boxes are perfectly fine to be screwed into roof deck.

San Jose does not require structural design if no more than 40 lbs per attachment point. Other cities have similar numbers. Similar in Oakland, but they do want a drawing of roof trusses.

My city was something like: parallel to roof, 2x4, 24" OC, no stamp needed.

I think that is allowing lag screws into sheathing. I intend to hit rafters.

I really, really doubt any place supports lag screws into sheathing. Neither plywood nor OSB are rated to hold much of anything with just screws going into them (OSB probably zero).

My Unirac plans (submitted to the city) specified that they were to be embedded in rafters.

I missed a few rafters on the first set I installed and spent a lot of time fixing after gluing. For the second set I installed, I checked for bursting etc from underneath before gluing anything down. Not sure I saved any time, but at least I saved the work of hacking away at it later.My own place, going to take my time and do the best I can.

At least the topspeed system just requires screws into sheathing, they do use 4 screws per mount, and aren't going to suitable for some areas with heavy winds, or snow load requirements. Here is there engineering report and tables: https://snapnrack.com/wp-content/uploads/2023/08/TopSpeed-22-02141-Certification-Letter_cert.pdf (they also have engineer stamped cover letters for this report for many states)I really, really doubt any place supports lag screws into sheathing. Neither plywood nor OSB are rated to hold much of anything with just screws going into them (OSB probably zero).

I used the Quickbolt 2 with the Tamarack racking.

www.solar-electric.com

www.solar-electric.com

They also sell QB2 without the L brackets since Tamarack includes that with their racking.

I’ve also used the Flashfoot with Tamarack on another project. No leaks on either but the QB2 is much easier to install.

www.ironridge.com

www.ironridge.com

QuickBOLT Multi Roof Mount 5/16 X 4" QuickBOLT2 Kit with 3" Microflashing Individual

QuickBOLT Individual Multi Roof Mount 5/16 X 4" QuickBOLT2 Kit with 3" Microflashing

They also sell QB2 without the L brackets since Tamarack includes that with their racking.

I’ve also used the Flashfoot with Tamarack on another project. No leaks on either but the QB2 is much easier to install.

FlashFoot2®

The strongest attachment in solar. IronRidge FlashFoot2® raises the bar in solar roof protection. The unique water seal is both elevated and encapsulated, delivering redundant layers of protection against water intrusion.

42OhmsPA

What's in a title?

Chiming in as another happy Tamarack user for my roof arrays. You can order the shorter lengths and splice to avoid freight shipping.

I used uni/super strut on my ground mount, in my opinion the Tamarack was way easier to work with overall.

I used uni/super strut on my ground mount, in my opinion the Tamarack was way easier to work with overall.

Similar threads

- Replies

- 16

- Views

- 1K

- Replies

- 5

- Views

- 313