It's the "which oil" thread of engine forums...Quoted for truth! This is about as productive as most of the threads in the off topic section discussing religion and politics.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Compress or not, flexible busbar or not

- Thread starter Cheap 4-life

- Start date

Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

There’s been a lot of useful information discussed on this thread regarding this topic. Just because a person thinks it should be done how they do it does not make this discussion useless.. and yes which engine oil you use matters along with how often it’s changed..

Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

Kinda shows the flexibility. I’m more interested in how much they flex in and out. Mine do flex slightly in and out and that should be enough to prevent busbar sliding or the need for re torquingFrom last year. Shows the flexibility:

Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

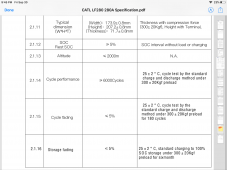

This is from the CATL cells data sheet that I ordered.

It says several times 300kgf preload.. to me that means to apply 300kgf at low SOC which is preload.. what yas think? that also seems like it’s suggested 300kgf does not have to be kept through the entire SOC (with springs or whatever) since it says set the cell at 300kgf preload.. am I reading to much into the use of the word preload..

It says several times 300kgf preload.. to me that means to apply 300kgf at low SOC which is preload.. what yas think? that also seems like it’s suggested 300kgf does not have to be kept through the entire SOC (with springs or whatever) since it says set the cell at 300kgf preload.. am I reading to much into the use of the word preload..

Attachments

Last edited:

Surely they define the preload conditions somewhere in the document.This is from the CATL cells spec sheet that I ordered.

It says several times 300kgf preload.. to me that means to apply 300kgf at low SOC which is preload.. what yas think? that also seems like it’s suggested 300kgf does not have to be kept through the entire SOC (with springs or whatever) since it says set the cell at 300kgf preload.. am I reading to much into the use of the word preload..

Preload is an engineering term. It applies to beams, bearings, springs, and lots of other things.

Food for thought. 300kgf works out to be about 650lbs. Mine are compressed with a single centralized spring at about 550lbs to be on the safer side. That being said, from cold low SOC to a warm high SOC, a group of 8 cells moves the “spring plate” about 3/16” or .023” per cell. I’m wondering what the rigid fixture pressure would be if initially set at say 1/3 SOC then brought up warm & high SOC?

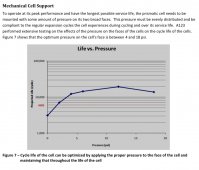

Where is that chart / data from?As you can see from the chart, once you compress/fixture the cells, calendar aging, depth of charge and environment become the concerns. Check out the re-range line value at the high point of the blue line. Lol

As many as 20,000 cycles at 12psi / 300kgf and that drops by ~33% to ~13,000 cycles at higher pressure of 18psi / 450kgf.

And lowering pressure to 6 psi / 150kgf drops cycle life to about the same ~13,000 cycles before it drops off a cliff below that.

300kgf with an upper limit of 450kgf and a lower limit of 150kgf was close to what I recall EVE recommending through backchannels in early 2021 when the information about cell pressure / clamping first came onto the scene…

Here’s the link to the papers,( chart is on pg32) lots of info;Where is that chart / data from?

As many as 20,000 cycles at 12psi / 300kgf and that drops by ~33% to ~13,000 cycles at higher pressure of 18psi / 450kgf.

And lowering pressure to 6 psi / 150kgf drops cycle life to about the same ~13,000 cycles before it drops off a cliff below that.

300kgf with an upper limit of 450kgf and a lower limit of 150kgf was close to what I recall EVE recommending through backchannels in early 2021 when the information about cell pressure / clamping first came onto the scene…

Pretty crazy huh? Yeah, the right side where the blue line ends is probably where things got gooey. There’s not much difference between 10 and 12 psi, so I went with 10.

Last edited:

What a fantastic paper! Thanks.Here’s the link to the papers,( chart is on pg32) lots of info;

Pretty crazy huh? Yeah, the right side where the blue line ends is probably where things got gooey. There’s not much difference between 10 and 12 psi, so I went with 10.

So it is not Eve 280 Ah cells but is is an I dependent verification of the importance or pressure on LiFePO4 cells to extend cycle life.

I also found figures 8 and 10 interesting, especially for those thinking about building rigid fixtures…

Here’s something else I just came across.

I think Eel battery mostly sells CATL cells and it’s seam they think it’s almost mandatory. The following is from the website; eelbattery.myshopify.com

LiFePO4 Cell Compression

SEPTEMBER 13, 2022

Share

What is Cell Compression?

Cell compression is quite literally squeezing/fixturing the outer aluminum case of LFP (LiFePO4) cells to prevent delamination of the internal components. Delamination leads to a reduced lifespan of the cells, as well as additional stress on electrical terminals. Internal forces are constantly acting on a thin aluminum case that is not strong enough to resist these forces. Lack of compression leads to damage of the cells, as indicated by swelling and premature battery failure.

Why Is Cell Compression Needed?

With the latest technology of LFP cells, many advances have been made to increase how much energy can be stored in a given volume. Engineers in general regularly face the challenge of fitting “more” into “less”. Sometimes to accomplish such a challenging task, compromises must be made. In this case, to create more space, a thinner, less structurally integral material has been chosen.

The thin aluminum case cannot withstand the internal forces exerted when the cells are charged, but the new design never expected the cells to be used on their own. The greater majority of these LiFePO4 cells on the market today are originally intended for use in Electric Vehicles (EVs). Automakers and pack manufacturers are already designing the packs with compression in mind because the demands of a solidly held pack in an electric vehicle where vibration is guaranteed are much more intense than a stationary solar power system. By using a single compression fixture on an entire pack as compared to many thick plastic cases, significant space and weight is saved, leading to higher capacities in the same space.

When Is Cell Compression Needed?

More times than not, cells will require compression. 95% of all aluminum-cased LFP cells on the market require compression. While the exact wording varies, most high-quality cell manufacturers will make notes in their data sheets.

Aluminum case batteries that do not require compression do in fact exist, however, they are rare. Asking the vendor you are purchasing the cells from is usually a good idea, however not all vendors are fully educated with regard to the engineering considerations of each and every battery and manufacturer requirements.

How To Build A Cell Compression Fixture

Cell compression fixtures will vary extensively. Every application is different, for example, a large array of cells in an electric vehicle will have many more cells to fixture, than a simple 4-cell pack used in an RV or camper. Advanced builds like this will have far more details than we can cover in this article. Some fixtures take advantage of plastic or metal banding, while others utilize threaded rods and end plates. Care must be taken in selecting materials that are able to resist the forces exerted by the cells.

A simple cell compression fixture that is sufficient for most stationary packs used in solar and off-grid applications can be built using some simple materials sourced at a local hardware store. In the video shown here, you can learn our recommended procedure for building a compression fixture that will provide enough compression to get you started and prevent premature degradation. This design is not perfect for every application, but can be used as a starting point. Members of the DIY community like this design due to its simplicity, however, other members have added coil springs, additional reinforcement, and many other methods to create a smoother and more even compression fixture..

Important Considerations

Cells will swell if they are charged over 3.4v regardless of the rate of charge.

Cell-swelling is based on the state of charge, not the rate of charge. Once a battery swells, it’s permanent damage that will make your pack a headache for the rest of its life. When you are preparing your battery pack for use, you may choose to top-balance your cells. When performing this process, you may think that you can opt-out of compression since it’s a slow rate of charge. This thought process is a MISTAKE and will cause major difficulty for your cells. Swollen cells that are re-compressed apply immense pressure to the outer layers of plates, whereas keeping an already-flat cell still flat applies even pressure to all plates throughout the battery.

I think Eel battery mostly sells CATL cells and it’s seam they think it’s almost mandatory. The following is from the website; eelbattery.myshopify.com

LiFePO4 Cell Compression

SEPTEMBER 13, 2022

Share

What is Cell Compression?

Cell compression is quite literally squeezing/fixturing the outer aluminum case of LFP (LiFePO4) cells to prevent delamination of the internal components. Delamination leads to a reduced lifespan of the cells, as well as additional stress on electrical terminals. Internal forces are constantly acting on a thin aluminum case that is not strong enough to resist these forces. Lack of compression leads to damage of the cells, as indicated by swelling and premature battery failure.

Why Is Cell Compression Needed?

With the latest technology of LFP cells, many advances have been made to increase how much energy can be stored in a given volume. Engineers in general regularly face the challenge of fitting “more” into “less”. Sometimes to accomplish such a challenging task, compromises must be made. In this case, to create more space, a thinner, less structurally integral material has been chosen.

The thin aluminum case cannot withstand the internal forces exerted when the cells are charged, but the new design never expected the cells to be used on their own. The greater majority of these LiFePO4 cells on the market today are originally intended for use in Electric Vehicles (EVs). Automakers and pack manufacturers are already designing the packs with compression in mind because the demands of a solidly held pack in an electric vehicle where vibration is guaranteed are much more intense than a stationary solar power system. By using a single compression fixture on an entire pack as compared to many thick plastic cases, significant space and weight is saved, leading to higher capacities in the same space.

When Is Cell Compression Needed?

More times than not, cells will require compression. 95% of all aluminum-cased LFP cells on the market require compression. While the exact wording varies, most high-quality cell manufacturers will make notes in their data sheets.

Aluminum case batteries that do not require compression do in fact exist, however, they are rare. Asking the vendor you are purchasing the cells from is usually a good idea, however not all vendors are fully educated with regard to the engineering considerations of each and every battery and manufacturer requirements.

How To Build A Cell Compression Fixture

Cell compression fixtures will vary extensively. Every application is different, for example, a large array of cells in an electric vehicle will have many more cells to fixture, than a simple 4-cell pack used in an RV or camper. Advanced builds like this will have far more details than we can cover in this article. Some fixtures take advantage of plastic or metal banding, while others utilize threaded rods and end plates. Care must be taken in selecting materials that are able to resist the forces exerted by the cells.

A simple cell compression fixture that is sufficient for most stationary packs used in solar and off-grid applications can be built using some simple materials sourced at a local hardware store. In the video shown here, you can learn our recommended procedure for building a compression fixture that will provide enough compression to get you started and prevent premature degradation. This design is not perfect for every application, but can be used as a starting point. Members of the DIY community like this design due to its simplicity, however, other members have added coil springs, additional reinforcement, and many other methods to create a smoother and more even compression fixture..

Important Considerations

Cells will swell if they are charged over 3.4v regardless of the rate of charge.

Cell-swelling is based on the state of charge, not the rate of charge. Once a battery swells, it’s permanent damage that will make your pack a headache for the rest of its life. When you are preparing your battery pack for use, you may choose to top-balance your cells. When performing this process, you may think that you can opt-out of compression since it’s a slow rate of charge. This thought process is a MISTAKE and will cause major difficulty for your cells. Swollen cells that are re-compressed apply immense pressure to the outer layers of plates, whereas keeping an already-flat cell still flat applies even pressure to all plates throughout the battery.

Sounds as though you’ve been tracking this LiFePO4 space for a while…There’s an amazing amount of good info out there, but every year it’s getting harder to find the cream out of the mounds of mostly crap background. It use to be so easy to do a search. Now it’s buried in incorrect results.

That paper was actually quite comforting in terms of the range of designs we’ve seen from various OTS LoFePO4 battery vendors - seems like there is a great deal of forgiveness on design parameters for pressure and even the ‘strap with strong packing tape’ designs probably can succeed to deliver close to states cycle life…

In case you have any source of good data, I’m also interested on calandra aging.

Designing 300kgf pressure fixtures to achieve cycle life of 6000 or even 20,000 cycles is all well and good, but if you only cycle once per day and calandra aging means cells will degrade to 80% of rated capacity after 5 years whether they are getting cycled or not, designing for over 2500 cycles is pretty much a waste of time…

cells will degrade to 80% of rated capacity after 5 years whether they are getting cycled or not, designing for over 2500 cycles is pretty much a waste of time…

[/QUOTE]

Unless they become damaged as the previous post (Eel) kinda hinted at. But time will be the teacher. When will we start to see things 2 - 3 year, never?

[/QUOTE]

Unless they become damaged as the previous post (Eel) kinda hinted at. But time will be the teacher. When will we start to see things 2 - 3 year, never?

Yikes. Wish I’d read that before I capacity/tested my 280Ah cells…Here’s something else I just came across.

I think Eel battery mostly sells CATL cells and it’s seam they think it’s almost mandatory. The following is from the website; eelbattery.myshopify.com

LiFePO4 Cell Compression

SEPTEMBER 13, 2022

Share

What is Cell Compression?

Cell compression is quite literally squeezing/fixturing the outer aluminum case of LFP (LiFePO4) cells to prevent delamination of the internal components. Delamination leads to a reduced lifespan of the cells, as well as additional stress on electrical terminals. Internal forces are constantly acting on a thin aluminum case that is not strong enough to resist these forces. Lack of compression leads to damage of the cells, as indicated by swelling and premature battery failure.

Why Is Cell Compression Needed?

With the latest technology of LFP cells, many advances have been made to increase how much energy can be stored in a given volume. Engineers in general regularly face the challenge of fitting “more” into “less”. Sometimes to accomplish such a challenging task, compromises must be made. In this case, to create more space, a thinner, less structurally integral material has been chosen.

The thin aluminum case cannot withstand the internal forces exerted when the cells are charged, but the new design never expected the cells to be used on their own. The greater majority of these LiFePO4 cells on the market today are originally intended for use in Electric Vehicles (EVs). Automakers and pack manufacturers are already designing the packs with compression in mind because the demands of a solidly held pack in an electric vehicle where vibration is guaranteed are much more intense than a stationary solar power system. By using a single compression fixture on an entire pack as compared to many thick plastic cases, significant space and weight is saved, leading to higher capacities in the same space.

When Is Cell Compression Needed?

More times than not, cells will require compression. 95% of all aluminum-cased LFP cells on the market require compression. While the exact wording varies, most high-quality cell manufacturers will make notes in their data sheets.

Aluminum case batteries that do not require compression do in fact exist, however, they are rare. Asking the vendor you are purchasing the cells from is usually a good idea, however not all vendors are fully educated with regard to the engineering considerations of each and every battery and manufacturer requirements.

How To Build A Cell Compression Fixture

Cell compression fixtures will vary extensively. Every application is different, for example, a large array of cells in an electric vehicle will have many more cells to fixture, than a simple 4-cell pack used in an RV or camper. Advanced builds like this will have far more details than we can cover in this article. Some fixtures take advantage of plastic or metal banding, while others utilize threaded rods and end plates. Care must be taken in selecting materials that are able to resist the forces exerted by the cells.

A simple cell compression fixture that is sufficient for most stationary packs used in solar and off-grid applications can be built using some simple materials sourced at a local hardware store. In the video shown here, you can learn our recommended procedure for building a compression fixture that will provide enough compression to get you started and prevent premature degradation. This design is not perfect for every application, but can be used as a starting point. Members of the DIY community like this design due to its simplicity, however, other members have added coil springs, additional reinforcement, and many other methods to create a smoother and more even compression fixture..

Important Considerations

Cells will swell if they are charged over 3.4v regardless of the rate of charge.

Cell-swelling is based on the state of charge, not the rate of charge. Once a battery swells, it’s permanent damage that will make your pack a headache for the rest of its life. When you are preparing your battery pack for use, you may choose to top-balance your cells. When performing this process, you may think that you can opt-out of compression since it’s a slow rate of charge. This thought process is a MISTAKE and will cause major difficulty for your cells. Swollen cells that are re-compressed apply immense pressure to the outer layers of plates, whereas keeping an already-flat cell still flat applies even pressure to all plates throughout the battery.

I didn’t get any noticeable swelling but I charged up to 3.65V with no fixture… (2020).

As the cost of OTS LiFePO batteries keeps coming down, I doubt I’ll ever build another DIY battery, but if I ever do, I’d do it so much more correctly than this first attempt…

Unless they become damaged as the previous post (Eel) kinda hinted at. But time will be the teacher. When will we start to see things 2 - 3 year, never?

My battery has been cycled for exactly one year now (though cells were purchased 2 years ago).

My plan is to perform a full capacity test annually to track degradation in maximum capacity so I’ll report back if I discover anything interesting when I finally get around to it…

Well there must be some data from the EV world by now - any indication how many years until EV driving range will be reduced to 80% of initial specification, even if it’s driven very little?Lab, prototype, sort run, calendar simulated degradation is one thing, but production run product used in real world situations and actual time will render the truth. Till then we’ll have to wait for feed back from guys like us.

Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

That’s seems rather fast to degrade to 80%.. that’s only 1825 cycles if it’s fully cycled everyday..cells will degrade to 80% of rated capacity after 5 years whether they are getting cycled or not, designing for over 2500 cycles is pretty much a waste of time…

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 20

- Views

- 521

- Replies

- 23

- Views

- 1K