Hi,

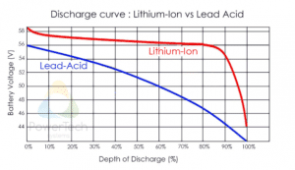

I made a previous post about my first project where everyone kindly helped and it seemed like I was way too short/low on my battery and panel - I am now upgrading a couple of things and I was wondering if I were to use my already purchased battery which was the 30ah lithium iron battery and add an extra battery of lets say HOPPECKE 12V DEEP CYCLE SOLAR PV Batteries 105AH "OR" a LEAD ACID Battery would I have any problems basically mix and matching them? would it actually work? or is it dangerous ?

Second question is would I be able to connect an additional 300w solar panel to an existing 100w panel? or do they need to be the same?

Many thanks for the replies in advance.

Regards,

I made a previous post about my first project where everyone kindly helped and it seemed like I was way too short/low on my battery and panel - I am now upgrading a couple of things and I was wondering if I were to use my already purchased battery which was the 30ah lithium iron battery and add an extra battery of lets say HOPPECKE 12V DEEP CYCLE SOLAR PV Batteries 105AH "OR" a LEAD ACID Battery would I have any problems basically mix and matching them? would it actually work? or is it dangerous ?

Second question is would I be able to connect an additional 300w solar panel to an existing 100w panel? or do they need to be the same?

Many thanks for the replies in advance.

Regards,