-C-

New Member

- Joined

- Oct 17, 2020

- Messages

- 15

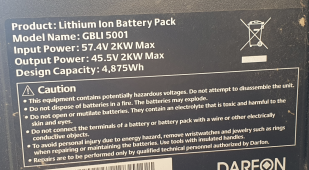

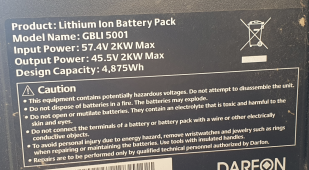

I've been offered this - seller is fair and flexible, price is somewhat dependent on how useful it'll be for me.

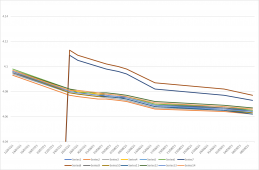

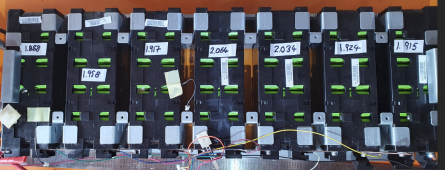

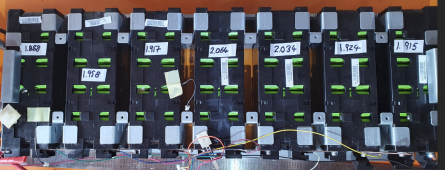

I can't get any sign of life out of the BMS, but that's likely due to the string voltages. Took out one row and this is what they measured at:

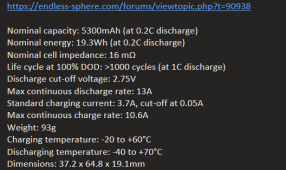

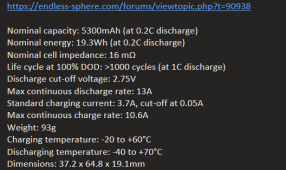

It's using these Boston Power Swing 5300 cells, which from what I've read are pretty good when new.

As the cells have been discharged well below the specced 2.75V. Is there any hope for them?

If they're likely to be usable or revivable, I'm thinking of reconfiguring it as 24V (my main inverter is 24V) and using a different BMS, as from what I've read the main weakness of these systems is the standard BMS. If that sounds sensible, does anyone have any recommendations for a suitable BMS?

Or should I just walk away?

Thanks

I can't get any sign of life out of the BMS, but that's likely due to the string voltages. Took out one row and this is what they measured at:

It's using these Boston Power Swing 5300 cells, which from what I've read are pretty good when new.

As the cells have been discharged well below the specced 2.75V. Is there any hope for them?

If they're likely to be usable or revivable, I'm thinking of reconfiguring it as 24V (my main inverter is 24V) and using a different BMS, as from what I've read the main weakness of these systems is the standard BMS. If that sounds sensible, does anyone have any recommendations for a suitable BMS?

Or should I just walk away?

Thanks