MarkSolar

Solar Enthusiast

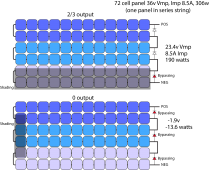

I have been curious about the effects of shade on my array. I have 24 panels wired in 3 strings of 8, 10kW total, they all get combined and go into one MPPT on a Fronius inverter. On a cloudless day with sun directly overhead I did 2 tests. I used a large umbrella that casts shade on ~1/2 of one panel. I used a heavy black rug to completely block one panel. Here's the loss in total array power output for the tests:

Theoretical power loss removing one panel: 4.2%

Actual power loss covering one panel with rug: 5%

Power loss with umbrella shading 1/2 of one panel: 8%

This surprised me, I've read so many accounts of dramatic reductions from partial shading that I assumed I would see very large reductions in output. Is it possible a single tracker on a string inverter is more efficient than expected, or am I not understanding something.

Theoretical power loss removing one panel: 4.2%

Actual power loss covering one panel with rug: 5%

Power loss with umbrella shading 1/2 of one panel: 8%

This surprised me, I've read so many accounts of dramatic reductions from partial shading that I assumed I would see very large reductions in output. Is it possible a single tracker on a string inverter is more efficient than expected, or am I not understanding something.