timselectric

If I can do it, you can do it.

- Joined

- Feb 5, 2022

- Messages

- 19,796

I use a $16 breaker. lolUnit price $883.42 ughhh

I use a $16 breaker. lolUnit price $883.42 ughhh

Which breaker?I use a $16 breaker. lol

Which breaker?

Can you please explain what this Anderson thing is and how to use itI used to turn my IMO off and on a lot when commissioning the system last year…now I rarely turn it off … there’s no reason lately.

The PV panels feed the combiner box …the.combiner box feeds the IMO … the IMO feeds a plastic weatherproof box which has a set of large Anderson connectors (and a MS SPD) which connect to the wire that run 65 ft to the solar trailer and it’s own seperate connection

/ cutoffs / SPD / fuse ….

when working on anything PV related I turn off the IMO and then unplug the Anderson connectors.. now all connections are disconnected from the panels to the solar gear…first with IMO ,then with an absolute wire disconnect , the Andersons.

if I’m going to mess with the actual panels I use gloves …

My IMO has been used about 50 times this summer under some degree of load… it works just fine.…

it is simi - protected from rain and UV , but if the plastic fails every 2-5 years from sunlight, remove the guts and install in a metal Box… OR …..go spend a hundred buck and totally replace it … that what we do with tires, fan belts and hoses… fluids and mufflers.

Can you please explain what this Anderson thing is and how to use it

?

Tim, I will send you an overview of the model I got…it’s called an SB 175 ..it’s the one of the ones you can use differing wires with 1/0 ( 6 ga + 1/0 …or 2 ga to 1/0) . I got the grey ones .. different colors can mean different things.I would like to see a link to the Anderson connector used. And if it's actually rated for higher PV voltages.

Not that it needs to be, if it's never disconnected under load.

Another pic .. with different specs…I would like to see a link to the Anderson connector used. And if it's actually rated for higher PV voltages.

Not that it needs to be, if it's never disconnected under load.

There are none on my recent grid tied system, done in may 23 (Perth).Australia has done a 180 on them too, but most of theirs were fitted up on the roof when they no doubt degraded and started leaking.

I'm very familiar with them. I have also used them for years. I like them because the contacts are self wiping (cleaning). I didn't realize that they were rated for 600vdc. As I have never needed them for anything above 100vdc. But it makes sense as long as you don't disconnect them under load. (That's scary at just 12vdc)Tim, I will send you an overview of the model I got…it’s called an SB 175 ..it’s the one of the ones you can use differing wires with 1/0 ( 6 ga + 1/0 …or 2 ga to 1/0) . I got the grey ones .. different colors can mean different things.

I bought all of my Anderson gear and crimps at Powerwerx …online, great place I thought…they have all the specs…and are very knowledgeable…

can’t speak for all of the models as there are too many …but I love using them..

I have never tried to unplug or plug one up under a decent load , but in an emergency i have known people who did… decent sparks can ensue…

Mine are mid sized ones ,I believe they are rated for 175 amps , 600 volts DC. . 10,000 disconnects no load , the 100 amp load disconnect rating is much less,.but I forget exactly.

It doesn’t matter much as in my case they are under no load as the IMO is turned off before they are opened and they are connected before the IMO is turned back on.

i used them for years on my snowplow and gravel spreader connections.. mounted in water proof boxes. . the 1/0 Wire is a bitch to crimp with their special thick lugs…there’s a ton more info on them if one wants to look.

pic follows …

Jim.

It's cheaper to just use ammonium nitrate and diesel fuel than dynamite. Farmers have easy access to both.Your instl isn't much concern, but others obviously have this on rooftop, on outside of house etc or are planning to do so..We don't want problems tracing back to some DIY Solar folk, now do WE? ?

Remember when you could buy dynamite for DIY until someone effed up??

View attachment 188983

If we can rethink the way we have done things, I know we all think to ourselves "next time I would change x, do y differently, make it better". Just trying to "work the problem", or at least consider whether it is a problem. It's a darn important little piece of plastic, perhaps...

And great, we agree metal enclosures might be a thing for these!

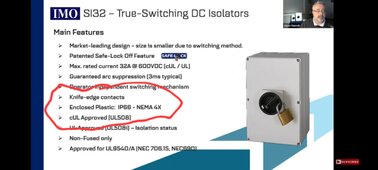

NEMA 4X, as you are probably aware. Now if it were only more UV resistant, until we come out and find via a (hopefully no more damage than) melted glob that UV degradation resulted in a loss of of said IP rating and subsequent failure.The IMO molded case is IP67 rated and NEMA 4.

Indoors, right?? Weren't you talking future ground mount?? What would be your plan for array disconnect?? I'd like to see more input from highly respected members, not just Doc (highly respected) and myself (a wildcard no doubt ?)I use a $16 breaker. lol

Electricians around the world install pvc conduit outdoors, you seem to miss that point. It is done for corrosion resistance, your counter argument about "plastic" is really baseless.NEMA 4X, as you are probably aware. Now if it were only more UV resistant, until we come out and find via a (hopefully no more damage than) melted glob that UV degradation resulted in a loss of of said IP rating and subsequent failure.

Agree, putting it in a metal enclosure is still some concern both in terms of water ingress and perhaps arc safety (?). There was something in the IMO manual about the non enclosed switch itself being IP66 "front face only" = complete BS to me.

As for the IP rating, it is IP66 for cover and enclosed plastic. It is in the video in the post above but you obviously didn't watch it. If you were to actually hold this in your hand, you would know why it is IP rated.Ah, there it is. It's really telling to me that it's UL94 fire rated not to burn...very long. Let's just say outdoors consideration should be given to combustibilty of mounting locations??

View attachment 189080

67 enclosed, thx, I posted that.IP66 for cover and enclosed plastic

Not misrepresenting. I'm saying it fails in the field. (But trying to misrepresent a product that was designed and tested for the application is just trying to be argumentative.

Looking better all the time. And it was post #5 we could have been done here a loooonng time agoStop charge and loads on your inverter, then it is safe to disconnect an MC4 to break the circuit.

67 enclosed, thx, I posted that.

Not misrepresenting. I'm saying it fails in the field. () ( <- can you really put a smiley on that?)

Actually, I found the video interesting and I agree with the video where it states to not install additional isolation if not needed. If rooftop solar is installed with micro inverters or other RSD devices at module level, there is no need to install additional isolation on the roof as was commonly done in the past.Look, I understand your point in starting this topic was to poo-poo the videos / decisions. However it may have surprised you a discussion broke out !

Well, this is solved. My apologies to Doc Z and all, the video and manual disagreeIt is IP66 for the cover and enclosed plastic. It's in the video you haven't watched yet.

This is a good point. I immediately noted the 50 degrees Celsius, or 122 degrees Fahrenheit. We had three days summer 2019 at 121 degrees Fahrenheit, what might the temperature have been within unventilated and exposed to sun enclosures? This is not my main thought.

This thread wouldn't be complete without the oft-repeated terrifying Australian pictures...It doesn't fail in the field, only in some people's twisted minds.