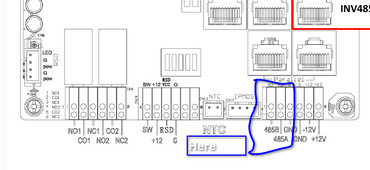

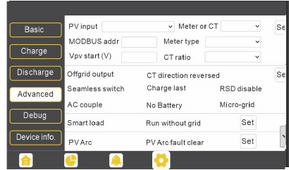

Been looking at possible replacement inverters, and the EG4 18Kpv seems like a pretty good match for my needs. One "feature" which I had hoped to implement in my system was adding a dump load (hot water heater element) to make use of extra power when the batts are close to fully charged. From looking at the 18Kpv manual, the inverter has a set of NO/NC relay contacts (the "DRY contacts") separate from the generator contacts, but there is nothing in the manual on how to use/program that relay.

Does anyone know if it is possible to control this DRY contact relay based upon battery SOC or voltage? How about setting separate on and off voltage levels so one can build in some hysteresis?

Thanks

Does anyone know if it is possible to control this DRY contact relay based upon battery SOC or voltage? How about setting separate on and off voltage levels so one can build in some hysteresis?

Thanks