Rui Ponte

New Member

- Joined

- Nov 25, 2019

- Messages

- 73

12kW inverting / charging

Super proud of my build! ?

Thank you all for sharing your knowledge. That's what made this build possible! ?

Note: I made some upgrades from 2020 to 2022 and, therefore, some pictures may be outdated!

- 3 x Victron Multiplus II 5000VA in 3-phase configuration

- 12 x 270W Jinko coupled with Victron Smartsolar 250/60

- 12 x 280W JA Solar coupled with Victron Smartsolar 250/60

- 8 x 410W JA Solar coupled with Victron Smartsolar 250/70

- Cells: 32x280Ah LiFePo4 in 16S2P 48V, 20mm x 5mm custom built busbars and 70mm2 cabling

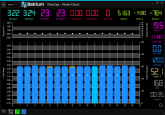

- BMS: Batrium WM4 + 16 BlockMons 8

- DC Breaker: 150A Carling Tech (FA1-B0-14-815-12A-BG)

- 42U rack mount

- Custom 680x420mm steel grate shelves

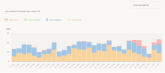

- Power bill minimization:

- Peak shaving to minimize contracted power:

- Flexible load: EV charger adjusting power dynamically

- If above is not enough, the following loads can be interrupted: heat pump; pool pump; house dehumidifier; other

- Arbitrage: charging from grid and/or selling to grid, for profit

- Load shifting to maximize peak shaving and arbitrage:

- EV charger: flexible charging to achieve the user-set charging target

- Heat pump: flexible temperature setpoints + thermal storage in heated floor;

- Pool pump: flexible hourly/daily working hours, to achieve weekly working hours target

- House dehumidifier: flexible humidity target

- Peak shaving to minimize contracted power:

- Power Backup: if the grid goes out, the entire house switches to island-mode seamlessly (less than 20ms).

- Some specs:

- Inputs for the system's decision-making:

- Next-day PV production forecast

- Electricity prices: next-day hourly wholesale price (for sale) & consumer tariff

- User setpoints

- The brains: a Home Assistant server connecting everything, with most programming made in MQTT.

- Inputs for the system's decision-making:

Super proud of my build! ?

Thank you all for sharing your knowledge. That's what made this build possible! ?

Note: I made some upgrades from 2020 to 2022 and, therefore, some pictures may be outdated!

Attachments

Last edited: