If you think in watts, just remember that watts = amps X volts. Two amps at 120V is 240watts.

The conventional way of expressing your panel wiring would be 2S8P. That is eight parallel strings of two panels in series. That's OK, but I don't really think it's that optimal. Is each parallel string protected with a fuse or breaker? If not, I believe that could be a rather serious code violation. Whenever you have three or more parallel strings of panels, they are supposed to be fused/breakered.

I think you'd see less voltage drop due to wire resistance if you upped your string voltage. With 16 panels, you might try 4S4P. That is four parallel strings of four panels each. You'd be getting 8A +8A +8A +8A at ~120VDC. That would be 4 12A breakers in the combiner box I illustrated above. You generally select a breaker that is rated for 1.5X the running amperage. Alternatively, you could do 3S5P, or 5S3P, though you'd need to set aside one panel.

There are two opposing forces at work here. In general, you want to get voltage as high as possible to reduce wire resistance to a minimum. There are resistance calculators to determine exactly what your voltage drop will be at a certain voltage with a certain wire. Here's one.

This free voltage drop calculator estimates the voltage drop of an electrical circuit based on the wire size, distance, and anticipated load current.

www.calculator.net

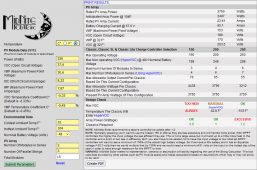

The opposing issue is that the inverter works a little harder to transform higher voltage down to battery voltage. This is a curve that is usually published by the manufacturer. I don't know if Mpp publishes one. In your case, the sweet spot for voltage might be somewhere around the middle of whatever your unit's minimum and and maximum voltages are. I'd guestimate that might be somewhere around 90-120VDC. You should dive deeply into your owners manual to answer those questions, but I'd say you are likely to get best performance somewhere between 3S5P and 5S3P.

I'd carefully read through the manual again and see if you spot a recommended optimal voltage. Then you wire your panels in the scheme that gives you that voltage.