I will first note that I am only working with a 12v system and have no plans to implement ac so from what I read that does limit the possible dangers.

I got, what I hope is, the remainder of my kit yesterday and realized I dont have the first clue about safety of installing this stuff. Even the Will Prowse videos that claim to be for beginners he seems to assume a previous background in electrical wiring and doesnt really explain about anything when installing stuff.

Likewise with all other so called basic videos I have seen so far. I have seen no mention of safety precautions that are required when touching wires in the system. Is that because they are not dangerous. I certainly thought it better to check that here first.

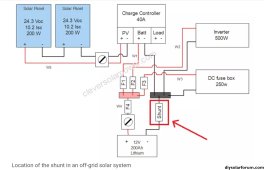

The general consensus when I was asking about breakers and isolators were that they are just a convenience rather than a safety measure and that fusing the wires is all that is required for safety. I just realized yesterday though, once your connection is live to the battery how do you then disconnect and mess about with wires without risk of electrocution.

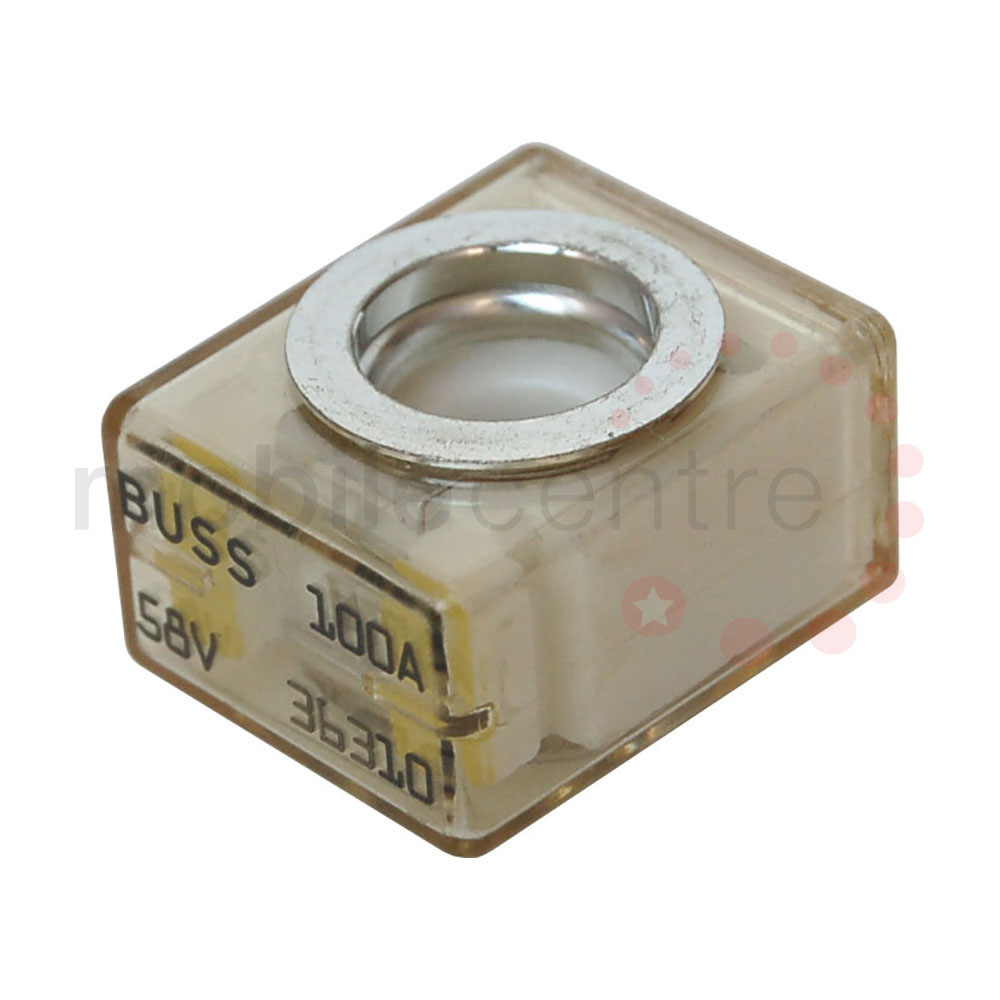

So I thought I would keep it simple and only use megafuses for the links between battery to blade fuse box and battery to mppt. As such though how do I disconnect safely to work on the system because the act of disconnecting, without a breaker/disconnect must then entail touching a live wire to disconnect the fuse. Is this safe to do or not?

Oh btw the way on wills minimalist youtube video I am confused as to why he connects the mppt to the blade fuse block rather than the battery, the latter which seems to be most common practice in other setups. Again, he doesnt bother explaining this at all. Anyway, since this seems to be the exceptional case I am just going to connect them to the battery but I am interested to know why he did it like that.

I ask for both the link to the battery to blade fuse block and battery to mppt. Also what about the panels to the mppt? How to disconnect those since, as I made in another post, I have not used fuses or a dc isolator. In antoher reply elsewhere they mentioned to simple disconnect the positive from the panels to the mppt, but again, is this safe to touch since it will be live.

I got, what I hope is, the remainder of my kit yesterday and realized I dont have the first clue about safety of installing this stuff. Even the Will Prowse videos that claim to be for beginners he seems to assume a previous background in electrical wiring and doesnt really explain about anything when installing stuff.

Likewise with all other so called basic videos I have seen so far. I have seen no mention of safety precautions that are required when touching wires in the system. Is that because they are not dangerous. I certainly thought it better to check that here first.

The general consensus when I was asking about breakers and isolators were that they are just a convenience rather than a safety measure and that fusing the wires is all that is required for safety. I just realized yesterday though, once your connection is live to the battery how do you then disconnect and mess about with wires without risk of electrocution.

So I thought I would keep it simple and only use megafuses for the links between battery to blade fuse box and battery to mppt. As such though how do I disconnect safely to work on the system because the act of disconnecting, without a breaker/disconnect must then entail touching a live wire to disconnect the fuse. Is this safe to do or not?

Oh btw the way on wills minimalist youtube video I am confused as to why he connects the mppt to the blade fuse block rather than the battery, the latter which seems to be most common practice in other setups. Again, he doesnt bother explaining this at all. Anyway, since this seems to be the exceptional case I am just going to connect them to the battery but I am interested to know why he did it like that.

I ask for both the link to the battery to blade fuse block and battery to mppt. Also what about the panels to the mppt? How to disconnect those since, as I made in another post, I have not used fuses or a dc isolator. In antoher reply elsewhere they mentioned to simple disconnect the positive from the panels to the mppt, but again, is this safe to touch since it will be live.