robbob2112

Doing more research, mosty harmless

But then you have the complication about whether the manufacturer recommends ferrules or not. For North American equipment, it's usually not included in the instructions and would be an off label use.

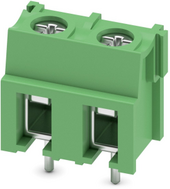

Phoenix contact makes the 2 awg terminal on my CC

Phoenix contact makes 2 awg ferrules:

But my manual does not say to use them. I haven't decided if I think I know better.

Ferrule use really depends on the design of the screw terminal.

Those with a screw that pushes down a cup shaped wedge always use bare wire. The cup shaped wedge gathers the wires and pushes evenly without letting them be damaged or slide past the slides.

Those with spring connectors all use bare wire, but not all are designed for stranded and solid. They can be designed for one or both depending on the MFG. This is the type Victron uses in the MPPT that it calls out bare stranded wire. This is also how the WAGO connectors work for solid wires except they have a leaver to press verse totally spring loaded.

The bare stranded terminal blocks go into the spring and push the spring up and contact the whole wires and then it pushes them flatter to get a larger contact spot. This type typically has a screw on the top to improve the pressure.

The ones for solid wire then to have a hook that faces the wires and bites into the wire. The bites into the wire would damage stranded but not solid.

Those with just a screw like is typically found in a breaker not designed for 2 wires is made for solid wire and it is preferable to use ferrules when using stranded wire. Note, those breakers designed for two wires have a plate it pushes down but they are still designed for solid wire so ferrules are still preferred.

Victron MPPT have both types of terminal blocks. In their manual they explicitly call out the type of wire in their equipment manuals.