AgroVenturesPeru

New Member

- Joined

- Sep 19, 2020

- Messages

- 411

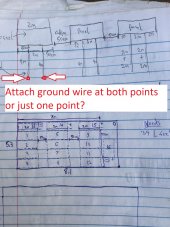

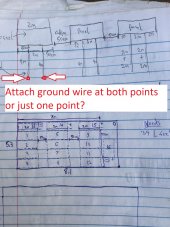

Hello, How do you attach the ground wires to the panel array? Do you need to attach a separate wire for each support rail? or just attach a ground wire to one of the two support rails for each row of panels? Let me ask with a picture.

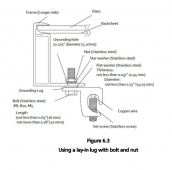

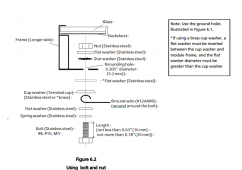

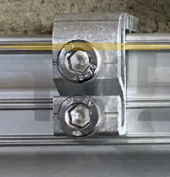

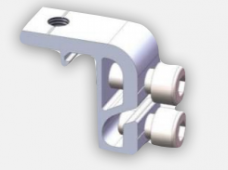

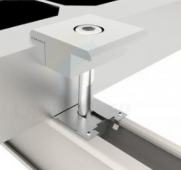

Here are the accesories I have to attach ground wires to the structures.

Also, how do you attach the wire? With pin terminals/ferrules? Ring terminals? Bare wire?

Here are the accesories I have to attach ground wires to the structures.

Also, how do you attach the wire? With pin terminals/ferrules? Ring terminals? Bare wire?

Last edited: