ThatCoolNerd

New Member

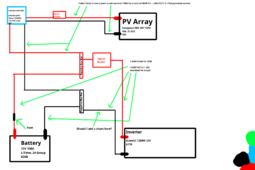

I am planning on building a small (~1.2kwh) mobile system that can be hauled around the home and yard for various AC applications. I do not have any needs for 12V DC output at the moment.

I would like some feedback regarding this diagram, as I'm a complete beginner. I have been reading and watching a lot of videos regarding solar, batteries, and electricity in general. I anticipate this little project will cost about $950-$1050 after shipping, tax, and purchasing of the tools (large/small wire crimpers/strippers), and materials.

I am not married to the idea of purchasing the EPEVER Tracer 2210AN as my charge controller. I was originally planning on going with a Victron BlueSolar MPPT 100/20, but the terminals are small and I've heard many beginners accidentally break them because of the flimsy terminals. If you have a suggestion for a better charge controller with proper terminals for my use-case, I'd love to hear!

I'm just trying to be more responsible and not only be more self-sufficient, but also learn a new skill.

Most importantly, does this look safe? Thank you all for reading!

P.S. Sorry the image is so big. It's my first schematic.

I would like some feedback regarding this diagram, as I'm a complete beginner. I have been reading and watching a lot of videos regarding solar, batteries, and electricity in general. I anticipate this little project will cost about $950-$1050 after shipping, tax, and purchasing of the tools (large/small wire crimpers/strippers), and materials.

I am not married to the idea of purchasing the EPEVER Tracer 2210AN as my charge controller. I was originally planning on going with a Victron BlueSolar MPPT 100/20, but the terminals are small and I've heard many beginners accidentally break them because of the flimsy terminals. If you have a suggestion for a better charge controller with proper terminals for my use-case, I'd love to hear!

I'm just trying to be more responsible and not only be more self-sufficient, but also learn a new skill.

Most importantly, does this look safe? Thank you all for reading!

P.S. Sorry the image is so big. It's my first schematic.