This is very frustrating. One chart says 90 deg 4/0 is good for 260A and one chart says 105 deg 4/0 is good for 440. Then I go to the Blue Sea Systems calculator and it says 90 deg 4/0 is good for 385A and 105 deg is good for 445A. Then I go to the Southwire calculator and it says 90 deg 4/0 is good for 455A in free air (whatever that means) and 90 deg 4/0 is good for 260A in conduit/direct burial.

That is quite a range of ampacity for 90 deg 4/0 cable: 260A-455A. The lower number is in conduit, the higher number is free air.

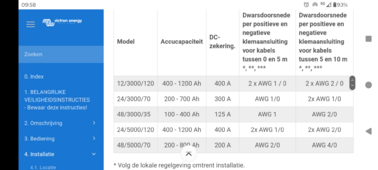

My MPII draws 325A @ 12V at max power. Victron recommends 2x2/0 cable for it. 2x2/0 90 deg cable in conduit is rated for 195A each, so 390A total. A single 90 deg 4/0 cable in conduit is rated for 260A. Seems like I would be way better off using 2x2/0 vs a single 4/0 for my MPII. I can tell you without a doubt that my 105 deg 4/0 cable I am currently using gets pretty warm with the MPII at max power.

The capacity of a wire to carry current is influenced by its sheath and the gauge of the individual strands within each wire.

The pure, simple cross-sectional area of copper determines how much current it can carry. However, this theoretical value is much higher than the actual rated value because it doesn't account for heat and cooling.

Airspace between the wires plays a role too—the finer the wires, the more airspace there is to retain heat. Therefore, for heating, thicker wire strands are better.

Thick wires are hard to bend, and when you do bend them more than a few dozen times, the copper gets brittle and can fracture. This is why single-stranded wire is used in fixed installations where there is no movement or vibration.

Finer wires can be bent many times without becoming stiff and can make tighter radius bends. Think of welding wire, for example.

The temperature rating of wire is also important. Different sheathing materials have varying abilities to dissipate heat and withstand repeated bending. In general, wire is rated in degrees Celsius for how hot it can get before failure.

Resistance to external factors is another consideration. Some sheaths can resist oil better than others, making them suitable for engine compartments. Others are better at resisting higher voltages.

For instance, 105°C welding wire consists of very fine strands in a rubber sheath, making it highly bendable.

THHN (Thermoplastic High Heat-Resistant Nylon-coated) wire is rated for high temperatures and is commonly used in dry locations. Comes in 75c and 90c versions

THWN (Thermoplastic Heat and Water-Resistant Nylon-coated) wire, on the other hand, is suitable for both wet and dry locations due to its water-resistant properties. Comes in 75c, 90c, and 105c versions.

There are other coatings that can hit 250c or more.

And when you shove it into conduit, or conduit on a roof, or in free air there are adjustments that get made.