krfish

New Member

- Joined

- Apr 21, 2022

- Messages

- 46

Hi,

I have helped a friend build a really big battery setup for his RV. Here is the basics:

* 1800 Amps of 12 battery

* Victron Shunt

* Victron victron multiplus split phase

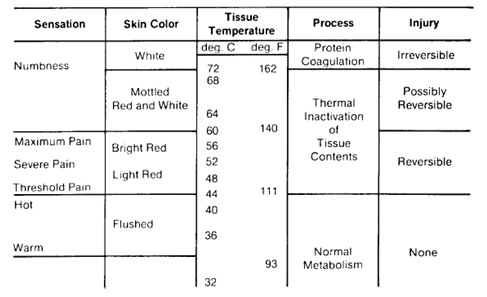

The question: when charging on city power, the inverter pushes almost 120 amps. The bus bar that is connected to the shunt gets to about 140 Fahrenheit after a few hours. We were cycling the battery for some testing, took quite a while to charge all the way back up (1800 amps - lol)

In any case, the bus bar never exceeds that temp and it take quite a while to get there. Seems normal, but I thought I would check with the community

Thanks!

I have helped a friend build a really big battery setup for his RV. Here is the basics:

* 1800 Amps of 12 battery

* Victron Shunt

* Victron victron multiplus split phase

The question: when charging on city power, the inverter pushes almost 120 amps. The bus bar that is connected to the shunt gets to about 140 Fahrenheit after a few hours. We were cycling the battery for some testing, took quite a while to charge all the way back up (1800 amps - lol)

In any case, the bus bar never exceeds that temp and it take quite a while to get there. Seems normal, but I thought I would check with the community

Thanks!