I do X-Ray + Neutron imaging to determine intercalation, morphology changes and degradation processes in my lab. Most of what I do (and the equipment/data generated) is confidential. Having said that, I rarely see these kinds of cells coming off the production line from companies we do these tests for. The cells I have personally (and that includes definite 'grade B' ones) have all been good so far - and even if some are not, the cost of a spare cell is insignificant. I'm three years in with my cells now without issues.

One of the reasons I buy cells from China is that they will sit on a boat for a couple of months and that will readily indicate any obvious issues like the one you identified - in case you don't have access to a CT scan.

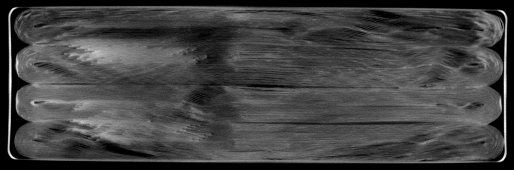

Attached you find a CT-scan from a brand new cell from a Chinese "Grade A" supplier, measured capacity and internal resistance were and still are within spec, no bulging, mechanical damage or other optical irregularity visible. The reason I commissioned the CT was low voltage after 3 months in warehouse and the picture tells you why. The electrode stack was probably improperly handled during assembly. This cell will be integrated in our company storage system and surveyed over time to learn how such a faulty cell behaves in a real world sub-C application. Conclusion: standard inspection with voltage, internal resistance and capacity measurement is not enough to be sure about quality, I would recommend to additionally store for extended time (min 3 months) with voltage measurement before integration. Another option would be to deep discharge and recharge to 5% SOC with 1 month storage time. However, I don't like cells to be at low SOC for extended periods of time. Maybe a 5-10min 3C discharge with IR monitoring could also reveal irregularities in the electrode stack (not tried). Looking forward to comments.

Attached you find a CT-scan from a brand new cell from a Chinese "Grade A" supplier, measured capacity and internal resistance were and still are within spec, no bulging, mechanical damage or other optical irregularity visible. The reason I commissioned the CT was low voltage after 3 months in warehouse and the picture tells you why. The electrode stack was probably improperly handled during assembly. This cell will be integrated in our company storage system and surveyed over time to learn how such a faulty cell behaves in a real world sub-C application. Conclusion: standard inspection with voltage, internal resistance and capacity measurement is not enough to be sure about quality, I would recommend to additionally store for extended time (min 3 months) with voltage measurement before integration. Another option would be to deep discharge and recharge to 5% SOC with 1 month storage time. However, I don't like cells to be at low SOC for extended periods of time. Maybe a 5-10min 3C discharge with IR monitoring could also reveal irregularities in the electrode stack (not tried). Looking forward to comments.