Zapper77

Renaissance Man

- Joined

- Jul 23, 2022

- Messages

- 2,321

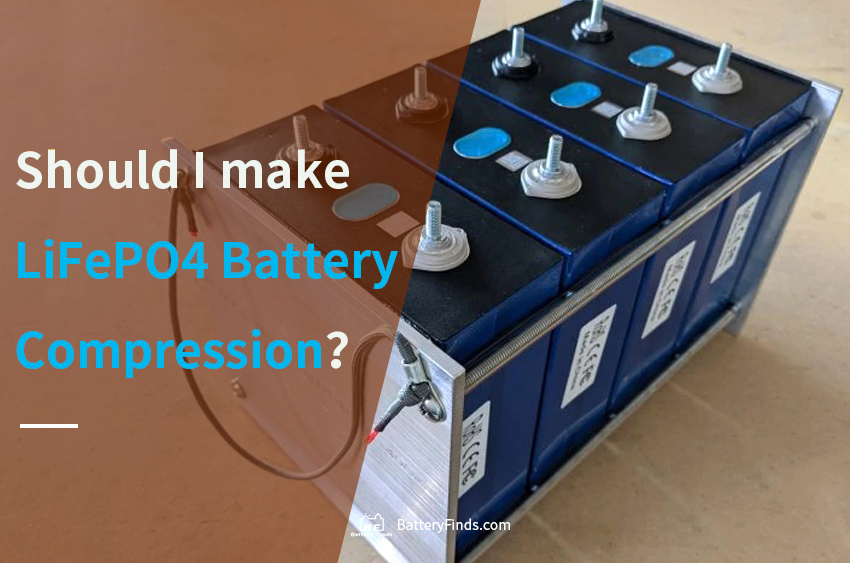

Looks like some form of black duck tape used to hold the cells together. Obviously the "professional" installer skipped a few basic cell protection features.What is the black tape around the edge of the battery and under it?