curiouscarbon

Science Penguin

- Joined

- Jun 29, 2020

- Messages

- 3,024

Hey all,

Been doing research about safe and fast charging/discharging of LFP cells.

Ran across a paper titled "Fast charging technique for high power LiFePO4 batteries: A mechanistic analysis of aging" [researchgate link]

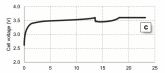

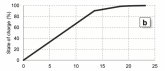

They discuss charging and discharging LiFePO4 cells at 4C in a constant ambient temperature of 23°C/73.4°F.

Pretty promising results. This suggests to me that running a peltier cooler or compressor type cooler to keep the cells at ~74F could drastically improve operation life, at the cost of some lost power to the temperature regulation apparatus. edit: The paper mentions cylindrical cells, so thermal conductivity of the pack is definitely on my mind.

Anyone have thoughts on this research?

Been doing research about safe and fast charging/discharging of LFP cells.

Ran across a paper titled "Fast charging technique for high power LiFePO4 batteries: A mechanistic analysis of aging" [researchgate link]

They discuss charging and discharging LiFePO4 cells at 4C in a constant ambient temperature of 23°C/73.4°F.

Full re- charges were achieved within ~20 min and 17% of capacity was lost after 4500 full charge/discharge cycles.

Pretty promising results. This suggests to me that running a peltier cooler or compressor type cooler to keep the cells at ~74F could drastically improve operation life, at the cost of some lost power to the temperature regulation apparatus. edit: The paper mentions cylindrical cells, so thermal conductivity of the pack is definitely on my mind.

Anyone have thoughts on this research?