Go2Guy

New Member

- Joined

- Feb 15, 2021

- Messages

- 40

---ORIGINAL TITLE----

Best charge controller settings to achieve 10%-90% usage on lifepo4 ?

EDIT-UPDATE and the ANSWER to this question. . . This post is a accumulation of all the great and wonderful information given to me by all the great people on this thread. I consolidated all of this into this post and is the result of many hours of research and consulting with the people of this forum. Again thanks every body!!!!! This would not be possible with out you guys. if you believe i missed something or want to amend something please comment on this thread but please do so in a way that can be consolidated and added to this post , . . this is really not my post per say but an accumulation of the knowledge of the people of this forum and thread. .

BEST SOLAR SETTINGS [SO FAR] FOR MAXIMUM LIFE 5,000-10,000+ cycle life

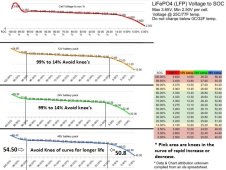

PREFACE The Best settings possible are actually to run from 14%-90% SOC and this has little to due with voltage [besides staying out of the high and low voltage knee] however this is not possible with out a columb meter,or even better a charge controller that operates off of this principle. . Most charge controllers are designed for lead acid and being that the case we have to enter in voltage numbers numbers, so even tho this is not the ideal way to go about it, its the only way for most of us with cheaper and/or older charge controllers. . Here best voltage numbers possible known by the great contributors of this group to achieve the maximum service life possible and put the batteries under as little stress as possible.

BULK/ADSORB 3.45-3.52 [heavily debated] but universally agreed no higher than 3.52 for max service life [3.52 is what victron recommends for max service life

[lower voltage= slower charge times IE [C rate] which is Good but potentially longer in absorb phase which is Bad]

[Higher voltage=faster charge times which is more stressful on cells, BUT less time in absorb phase which is good ] 3.5v-3.52 seems to be a good compromise fast and slow charge times NOTE: Lower voltages means charge rate will be reduced at high SOC and it will be harder to reach 100%. which is great if your shooting for less than 90% state of charge. !!!IMPORTANT NOTE: While the above mentioned data is recommended for minimum stress on the cells it is important that the voltage you set activates your BMS, to keep your cells balanced, if not your BMS becomes useless and will never actually balance , most BMS activate around 3.4 VERIFY at what voltage your BMS activates at . if you are not sure, it just may be better to higher voltage to ensure that its activated[Will Prowse goes all the way to 3.6v OR another option is to keep an eye on it and make sure the cells stay balanced.

FLOAT 3.35

3.35 volts is a good float voltage for high reserve capacity and minimal cell

degradation [3.35 is not really debated if maximum service life is the goal 3.4 if you want a little bit more reserve. Also 3.4 is recommended by many OEMS, however according to some data at 3.35 the cell is not really in a state of stress while anything higher than this it is. . your choice a little bit more conservative or a little bit more reserve ]

CUT OFF 3.1V [but a more ideal verifying the cut off voltage is is to run down battery pack under average load you will be running and then take note of what cell voltage drops off first, once the first cell drops off in voltage , measure the total pack voltage and set low cut off voltage to that measured total pack voltage.

NOTE: In certain high load situations you may get get voltage drop causing the system to "cut off" and shut down under high load even if its not necessarily towards the end of your desired capacity. . , if this is the cause. you may have to set the cut off lower voltage. . 3.1 is a conservative number 3.0-2.9 is recommended for high load situations, but remember this post is all about having the data to make educated choices if your goal is maximum service life and achieving a balance between functionality and maximum service life

OTHER NOTES:

TEMPERATURE-"""storage at high State of charge and high temperatures promoted such severe losses that the cells in question were unable to recapture capacity that they had lost reversibly""".DO NOT STORE IN HIGH SOC especially in HIGH HEAT, i dont have all the data yet but it seems operating under 32F or over 100F could/will causes damage[especially under 32] as a good precaution in short if your not comfortable the batteries are not comfortable, [this is a super generic but a safe conservative recommendation] As solutions to this conundrum people will run thermostat controlled heat pads and heat blankets for the winter [search the forum] and use water tanks/pads or ac for high temp operation [search the forum] .

Why temperature of lithium cells is important

Temperature is an important parameter that influences the aging of a lithium battery. At 35°C a lithium cell ages twice as fast as it does at 15°C. So if the battery’s useful life is 15 years at 15°C, it will be 7.5 years at 35°C. I summarize...

The Degradation Behavior of LiFePO4/C Batteries during Long-Term Calendar Aging

Abstract: With widespread applications for lithium-ion batteries in energy storage systems, the performance degradation of the battery attracts more and more attention. Understanding the battery’s long-term aging characteristics is essential for...

VOLTAGE LOSS Every connector in your system as well as wire length attributes to a certain amount of resistance and which results in voltage loss. in other words If you set the charge controller to 3.5 volts the battery may only see 3.2 due to this voltage loss You have to adjust the controller to compensate for the loss. you may also have different losses for different components in your system depending on where there located for example inverter is on a longer length of cable than where the charge controller is located.

HOW TO RESOLVE use a good quality meter . . .measure the terminals at the battery pack , measure the terminals at the controller or inverter, subtract the difference and add this difference to your charge controller or inverters settings. [when testing for charger controller you want to be under charge, for inverter you would want to be under discharge]. measure and test again to ensure this was sufficient compensation

STORAGE, batteries should be stored at about 40% SOC if going to be in storage for long periods of time. . high SOC storage causes premature cell degradation

DON'T BE AFRAID to use the battery at 100% if needed, calendar aging [definition, loss of capacity due to time alone] [thanks will for this input] also plays a role in long term degradation so if even if you baby these cells to the max, with old age you will still loose capacity. .so these numbers above are to baby the cells, but it is perfectly okay to use full 100% soc when you need it , when taken into consideration that the effect that calendar aging has on the battery. Its is a balance between the battery is loosing capacity on its own due to aging and you babying or not babying the cells , because of calendar aging some say who cares and just use it at 100% at all times , however that defeats the purpose of this post of attempting achieve maximum service life. . but it definitely doesn't hurt to use it when you really need it. .

Balance--(run batteries to a high SOC to trigger a good balance on your BMS 4 months or so, -as a maintenance. think of as a equalization ]

A great read by Joey on taking care of your cells https://diysolarforum.com/resources/how-charging-works-in-the-context-of-lfp-batteries.233/download

END POST

______________________________________________________________________________

ORIGINAL OPENING POST

i have spent about 6 hours reading thru google and and almost every relevant search result this website has as well as youtube. . and and my brain is on information over load. . I have a simple question, but i can only seem to find complicated answers and debates between people. I have several charge controllers and all in one units i will be setting up soon for family members and im looking to find what are the best settings to achieve a usage of between 10%-90% SOC on lifepo4 batteries. . . from everything i read it seems this is the safest for long term reliabilty [10-15 years or more if possible] . . but cant find info how to set the settings to achieve this .. . . . as we all know almost all charge controllers are designed for lead acid, so we are stuck with programming such parameters and have to make do with float and absorption settings. . what im looking for is the approximate voltages settings on a per cell basis for the following

bulk

absorption

float

low voltage cut off

also any other settings you recommended changing for lifepo4. .

should these numbers be different when under load?

any other considerations when using mpp units ?

the most straight forward answer i found was wills on his site, [ https://www.mobile-solarpower.com/diy-lifepo4-solar-battery.html ]

however his recommendations were based on 100% SOC which i prefer not to use since were looking for extra long life with this batteries ,so i prefer to stick to 80% however his post was the most straight forward answer of the 6 hours i have been searching online . . essentially looking for same answer but with 80% in mind. .

Last edited: