I have a balmar mc612 alternator connected to a 12V 1000Ah LiFePho4 bank. I contacted Balmar about what settings should be programmed in, and they were super helpful.

One of the items that they were insistent about installing was a alternator protection device.

Electric Car Parts Company is your one-stop-shop for affordable electric vehicle parts and components including batteries. Shop our selection and order now!

www.electriccarpartscompany.com

According to Balmar it will save your alternator and any electronics connected to the alternator in case the battery becomes disconnected either through some idiot switching the battery switch to OFF or the BMS taking the main battery offline. When the load is suddenly disconnected from an alternator, the output voltage spikes dramatically and at a minimum the diodes in the alternator are destroyed. The open circuit protection device that Balmar told me to buy keeps a load on the alternator at all times and supposedly keeps this from happening. I have never gone wrong listening to the Balmar tech support. I don’t have the courage to actually test the thing to see if it works though.

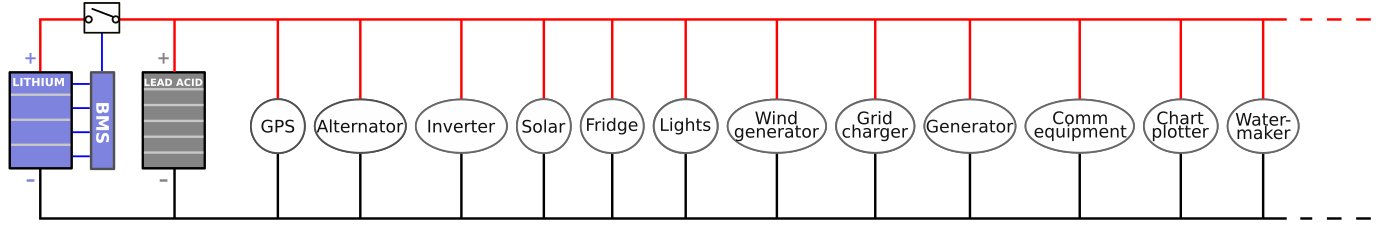

I presently have a similar hybrid system. Batt 1 is the house LiFePho4 1000 Ah. Batt 2 is a Lead Acid Starting Battery.

All of my charging sources (Balmar Alternator with MC612, Samlex inverter Charger, and Morning Star MPPT controller are programmed for Lithium charge profile). The BMS I use is the Electrodaucus SBMS0.

The sole exception is ONE 20 Amp Lead Acid Battery 120V charger that is connected to the starting battery for when I am on shore power or when the generator is on.

My usage profile is switch the 1/2/Both/Off battery switch to 2 (Start battery) start the engine or generator and let the alternator charge the starting battery for a few minutes as I pick up the anchor etc. Then I switch over to Battery 1 which is the House LiFePho4 and I just leave it like that.

My use model for the boat while at anchor or while sailing is one to two hours per day of generator run time to make water, cool down,the holding plate, and fast charge the Lithium Bank. At that time the small battery charger is also topping up the start battery. During the day the solar panels are charging the lithium bank.

Note that both banks are separated by the battery switch, but I can combine them if I want as was mentioned in the previous article. I have done that as the voltages are similar enough as to not cause any major problems, but in general the charge voltages of lithium batteries are higher than Lead Acid. If you permanently parallel connect your lead acid with the Lithium, you will overcharge the lead batteries and shorten their life.

My eventual goal is to move to all Lithium and get rid of the lead acid side completely. Unfortunately for me, the starting battery is only 6 months old, so I will continue using this hybrid system.

One of the other boats on the dock has a similar setup and he uses a battery to battery charger to top up his lead acid cells. I am only using the 120V AC charger I have because I already own it, and my stated goal is to move totally to Lithium when the last lead acid dies.

If I was going to keep a lead acid battery permanently, I would go with the Battery to Battery charger.

John.