Old_Skewler

Solar Enthusiast

Here is my current setup:

(3) EG4 48V Batteries

(2) Victron Busbar 4P 250A

(1) 400Lbs 12U Server Rack

- I am ordering (2) sets (black/red) of 3 wires same length, busbar to each battery

- I am also ordering (1) pair of black/red wires, same length, inverter to busbar

I suspect aside from the same cable lengths, the order of the connections is also important. I need to read more on this to sort this part out.

But my question now is regarding to where exactly would be a good location to mount the busbar in the server rack:

Option A: mount each busbar on the side of the server rack

Option B: mount both busbars on the top of the server rack, towards the front of the rack.

I understand different locations will require different wire lengths (and different costs!) but aside cost, any other thing I should be considering? For instance, is it okay (or smart) to bolt the busbar directly on the top shelf? Am I missing something here or is either doable, just a matter of preference?

Thanks in advance!

(3) EG4 48V Batteries

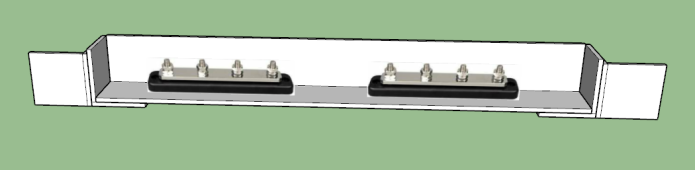

(2) Victron Busbar 4P 250A

(1) 400Lbs 12U Server Rack

- I am ordering (2) sets (black/red) of 3 wires same length, busbar to each battery

- I am also ordering (1) pair of black/red wires, same length, inverter to busbar

I suspect aside from the same cable lengths, the order of the connections is also important. I need to read more on this to sort this part out.

But my question now is regarding to where exactly would be a good location to mount the busbar in the server rack:

Option A: mount each busbar on the side of the server rack

Option B: mount both busbars on the top of the server rack, towards the front of the rack.

I understand different locations will require different wire lengths (and different costs!) but aside cost, any other thing I should be considering? For instance, is it okay (or smart) to bolt the busbar directly on the top shelf? Am I missing something here or is either doable, just a matter of preference?

Thanks in advance!