Awesome how complicated was that to set up. Is there any additional information or videos on how to set that up?Custom hardware/software, not something that can be bought off the shelf as a complete unit. It is ESP32 based with CT clamps connected via ADC over SPI, sending simulated meter info to the GSL inverter over RS485. I am emulating the Eastron SDM630 meter, as this appears to be the only one supported at the moment.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Lux Power LXP-LB-US 12k / GSL-H-12KLV-US with 200A AC Passthrough Current (US Market)

- Thread starter adamantium

- Start date

- Status

- Not open for further replies.

Not Aerosmith

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 389

Good to hear that elusivesed has his system up and running with no problems to report.

Nick Pan only response was "REALLY" when I told him that a DIY member determined that AC couple through the GEN port only works off grid.

He also told me tonight that Luxpower has updated their model and increased their prices. He said that the updated model was to add AC and DC breakers, which I guess to make it more like the Sol-Ark 15K all-in-one solution. Fromport bought the Luxpower version, so his Luxpower salesman should no more than my GSL salesman. Although, for me the new model is not really important, I need to make the GSL inverters that I bought to work.

Although, if I was on the fence about buying, I would be very interested in the second generation version of this inverter.

Nick Pan only response was "REALLY" when I told him that a DIY member determined that AC couple through the GEN port only works off grid.

He also told me tonight that Luxpower has updated their model and increased their prices. He said that the updated model was to add AC and DC breakers, which I guess to make it more like the Sol-Ark 15K all-in-one solution. Fromport bought the Luxpower version, so his Luxpower salesman should no more than my GSL salesman. Although, for me the new model is not really important, I need to make the GSL inverters that I bought to work.

Although, if I was on the fence about buying, I would be very interested in the second generation version of this inverter.

Last edited:

IMO it's not that difficult, but this is coming from the perspective of someone who designs hardware/software for a living. If this is not your area of expertise, there will be a steep learning curve. Definitely not beginner friendly, but it is doable if you spend enough time on it.Awesome how complicated was that to set up. Is there any additional information or videos on how to set that up?

Key areas to understand:

- Protocol documents of the Eastron SDM630 meter (Modbus RTU)

- ESP32 microcontroller design (electronics) and programming (software, your language of choice)

- General debugging skills. Determine baud rates, verify responses from inverter, etc.

This morning, I noticed my inverter relays were clicking on and off every few seconds. I don't really spend much time in the garage, so I haven't really noticed it before. The fix was simple - increase Vpv so the inverter does not attempt to pull power from the panels when not enough sun is available. It was left at the default setting of 140V, though my Voc is ~450V. Increasing it to around 300V largely resolved the excessive clicking issue, though I may need to adjust this a bit more.

Just sharing, as relays clicking may be interpreted as a problem when it is not. Will definitely reduce wear on the mechanical components though.

Just sharing, as relays clicking may be interpreted as a problem when it is not. Will definitely reduce wear on the mechanical components though.

Not Aerosmith

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 389

I like people that share their information.This morning, I noticed my inverter relays were clicking on and off every few seconds. I don't really spend much time in the garage, so I haven't really noticed it before. The fix was simple - increase Vpv so the inverter does not attempt to pull power from the panels when not enough sun is available. It was left at the default setting of 140V, though my Voc is ~450V. Increasing it to around 300V largely resolved the excessive clicking issue, though I may need to adjust this a bit more.

Just sharing, as relays clicking may be interpreted as a problem when it is not. Will definitely reduce wear on the mechanical components though.

Won't you lose the production from the sun between 140V to 300V? Also, won't the clicking now occur when the sun intensity is fluctuating at 300V on the solar panel?

It's related to the MPPT trackers. Basically what is happening during these early morning scenarios is open circuit voltage will initially measure beyond 140V, which turns on the system. However, right when the panels experience load with very little sunlight available, there will be a voltage drop, which drops string voltage below 140V, cutting it off. Cycle/repeat, until the panels can produce enough amperage to keep the MPPT trackers happy, which in my case would be somewhere above 300V. This phenomenon is very similar to attempting to start a car with a degraded battery - it may measure 12V at first, but the moment the starter relay is engaged, will drop voltage significantly while simultaneously not providing enough amperage to start the car. A "good" battery will still experience some voltage drop, but will also provide enough amperage to power the starter motor as needed.I like people that share their information.

Won't you lose the production from the sun between 140V to 300V? Also, won't the clicking now occur when the sun intensity is fluctuating at 300V on the solar panel?

Regarding lost production between 140V and 300V - in theory, yes. In practice, no... or very little. Inverters are not 100% efficient, and there is a baseline amount of energy required to keep the inverter circuitry itself powered on. Any plain old inverter (think 12 => 120V) will have some level of parasitic drain of 10's of watts just to remain 'on', even with no load attached. This number is typically higher on larger inverters... especially when approaching the scale of 10kW. If I had to choose between drawing 100W from the grid or battery, to capture 10-20W from the panels, I'd rather cut the panels and wait until they are ready for more production.

As for floating between 300V - the voltage output is not linear, and will very quickly reach peak, even with relatively little sunlight. Technically, this should be close to the Vmpp value provided by the solar panel datasheet. It is a balance between Voc (which is what the inverter first sees), Vmpp (voltage the panels are rated to be most effective, see datasheet), and the MPPT trackers, which constantly adjust load in an attempt to hunt for maximum power generation, for any given moment in the day.

Even with low current, the voltage is still high, and there will be an arc for every engagement/disengagement cycle. This will wear down any mechanical relay over time, so it's better to not do this excessively. Totally my fault for not setting this sooner or monitoring the behavior closely, but I can see how this will absolutely cause certain types of premature failure on any inverter.

Last edited:

Not Aerosmith

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 389

Excellent explanation!!!It's related to the MPPT trackers. Basically what is happening during these early morning scenarios is open circuit voltage will initially measure beyond 140V, which turns on the system. However, right when the panels experience load with very little sunlight available, there will be a voltage drop, which drops string voltage below 140V, cutting it off. Cycle/repeat, until the panels can produce enough amperage to keep the MPPT trackers happy, which in my case would be somewhere above 300V. This phenomenon is very similar to attempting to start a car with a degraded battery - it may measure 12V at first, but the moment the starter relay is engaged, will drop voltage significantly while simultaneously not providing enough amperage to start the car. A "good" battery will still experience some voltage drop, but will also provide enough amperage to power the starter motor as needed.

Regarding lost production between 140V and 300V - in theory, yes. In practice, no... or very little. Inverters are not 100% efficient, and there is a baseline amount of energy required to keep the inverter circuitry itself powered on. Any plain old inverter (think 12 => 120V) will have some level of parasitic drain of 10's of watts just to remain 'on', even with no load attached. This number is typically higher on larger inverters... especially when approaching the scale of 10kW. If I had to choose between drawing 100W from the grid or battery, to capture 10-20W from the panels, I'd rather cut the panels and wait until they are ready for more production.

As for floating between 300V - the voltage output is not linear, and will very quickly reach peak, even with relatively little sunlight. Technically, this should be close to the Vmpp value provided by the solar panel datasheet. It is a balance between Voc (which is what the inverter first sees), Vmpp (voltage the panels are rated to be most effective, see datasheet), and the MPPT trackers, which constantly adjust load in an attempt to hunt for maximum power generation, for any given moment in the day.

Even with low current, the voltage is still high, and there will be an arc for every engagement/disengagement cycle. This will wear down any mechanical relay over time, so it's better to not do this excessively. Totally my fault for not setting this sooner or monitoring the behavior closely, but I can see how this will absolutely cause certain types of premature failure on any inverter.

fromport

Solar Addict

It's related to the MPPT trackers.

My other hybrid aio inverter (megarevo) keeps the voltage at 80 volts constant and when over a certain amperage it switches to full mppt mode, prohibiting the on/off cycling in the beginning and at the end of the PV curve.

85 volt constant and after some amperage (unknown) has been reached it switches to true MPPT tracking.

Last edited:

Not Aerosmith

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 389

I'm sorry what do you mean by new production model? Have they changed something with this unit as opposed to the one you purchased?I found this ad online, which indicates that the GSL inverters new productions models are available:

View attachment 133152

Not Aerosmith

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 389

The 2 GSL inverters that I bought were a first production run. On mine the bottom access panel is painted black with exposed black hinges. I did not notice any differences in the specifications, but I have not compared them. I was concern that the new production run was on hold, until they have everything working. The fact that the the new production run has been release gives me hope that everything is now working. There is a new video on the GSL inverter posted herein made by GSL Energy on YouTube:I'm sorry what do you mean by new production model? Have they changed something with this unit as opposed to the one you purchased?

Last edited:

Not Aerosmith

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 389

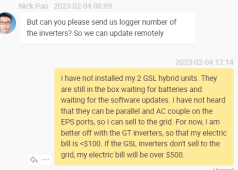

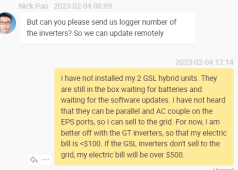

Received a response from my salesman:

I have told him this several times. The last time when I told him that the GEN port only works off grid, his response was "really". No other response, except now to send him my logger number of the inverters, so they can update remotely. GSL is a reseller with salesmen. I wished that I had done what fromport did and bought my 2 inverters from LUXPOWER. However, my only option now is to make work what I have bought.

When I receive the 560Ah of batteries, I do intend to install the 2 new GSL inverters and the 2 new GSL batteries. If AC couple do not work, I will simply pay to connect all the solar panels to the the 2 new GSL inverters. I do intend to add between 5-10 KW of solar panels, which will definitely be connected to the new hybrid inverters. My production last year with 15 KW of GT inverters was around 80% of my consumption and I have not bought an electric car .... yet.

I have told him this several times. The last time when I told him that the GEN port only works off grid, his response was "really". No other response, except now to send him my logger number of the inverters, so they can update remotely. GSL is a reseller with salesmen. I wished that I had done what fromport did and bought my 2 inverters from LUXPOWER. However, my only option now is to make work what I have bought.

When I receive the 560Ah of batteries, I do intend to install the 2 new GSL inverters and the 2 new GSL batteries. If AC couple do not work, I will simply pay to connect all the solar panels to the the 2 new GSL inverters. I do intend to add between 5-10 KW of solar panels, which will definitely be connected to the new hybrid inverters. My production last year with 15 KW of GT inverters was around 80% of my consumption and I have not bought an electric car .... yet.

Last edited:

I'm still baffled by the obsession with updating remotely. Why can't he just give you the files to do the update yourself?Received a response from my salesman:

View attachment 133186

I have told him this several times. The last time when I told him that the GEN port only works off grid, his response was "really". No other response, except now to send him my logger number of the inverters, so they can update remotely. GSL is a reseller with salesmen. I wished that I had done what fromport did and bought my 2 inverters from LUXPOWER. However, my only option now is to make work what I have bought.

When I receive the 560Ah of batteries, I do intend to install the 2 new GSL inverters and the 2 new GSL batteries. If AC couple do not work, I will simply pay to connect all the solar panels to the the 2 new GSL inverters. I do intend to add between 5-10 KW of solar panels, which will definitely be connected to the new hybrid inverters. My production last year with 15 KW of GT inverters was around 80% of my consumption and I have not bought an electric car .... yet.

Not Aerosmith

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 389

I agree and I even asked him to send me the file for updating the inverters myself. My salesman talks in circles or ignore questions that he doesn't want to answer. So I never received an update file, only request to send him logger numbers to update remotely.I'm still baffled by the obsession with updating remotely. Why can't he just give you the files to do the update yourself?

I was concern about world politics and didn't want to risk that something happens with trade relations between China and the USA. If so, I may never get the update, which is why I asked for the file.

one more thing you said you think GSL is just a reseller but that the manufacturer was Luxpower. I thought the UL listing was under GSL?I agree and I even asked him to send me the file for updating the inverters myself. My salesman talks in circles or ignore questions that he doesn't want to answer. So I never received an update file, only request to send him logger numbers to update remotely.

I was concern about world politics and didn't want to risk that something happens with trade relations between China and the USA. If so, I may never get the update, which is why I asked for the file.

Not Aerosmith

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 389

This question really needs to be answer by someone more knowledgeable about UL listings than me.one more thing you said you think GSL is just a reseller but that the manufacturer was Luxpower. I thought the UL listing was under GSL?

Sol-Ark have UL listings, but the manufacturer is Deye. I suspect that the UL listing is given to whoever pays for the product UL testing. Many companies have UL listed products even though they are made in other countries by other manufacturers.

Last edited:

Not Aerosmith

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 389

Robby is a DIY member and this was his response to the question about UL listings that he posted on March 10, 2022 in another thread.UL listings are for the one who paid for and did the testing and hold the certificate. You have to have the certificate for the hardware in order to put the logo on the product. You cannot just make your own duplicate board and it's automatically certified using someone else's certification. Most companies that share manufacturing lines will use the same PCB but the components on that PCB may be of a totally different Quality and this is especially true for Electrolytic Capacitors and FET's. There has never been a hesitancy on the part of the Chinese to Stick a UL, FCC and CE emblem on any of their products.

Last edited:

Luxpower_Gilbert

Luxpert @Luxpower USA Team

Give your wifi dongle sn# and they will give you update for the display, that you will have to do it by yourself and after that they will update the firmware Remotely of your inverter…I agree and I even asked him to send me the file for updating the inverters myself. My salesman talks in circles or ignore questions that he doesn't want to answer. So I never received an update file, only request to send him logger numbers to update remotely.

I was concern about world politics and didn't want to risk that something happens with trade relations between China and the USA. If so, I may never get the update, which is why I asked for the file.

Luxpower_Gilbert

Luxpert @Luxpower USA Team

Not Aerosmith

Solar Enthusiast

- Joined

- Sep 8, 2022

- Messages

- 389

Okay, I will give him the 2 dongles' serial number's. Only the serial numbers and not the PIN???Give your wifi dongle sn# and they will give you update for the display, that you will have to do it by yourself and after that they will update the firmware Remotely of your inverter…

There is no harm in giving him the serial numbers, since the inverters are neither installed nor connected to the internet. It is still my decision when the software is updated. Hopefully, by the time I get the batteries and install everything, the updated software will be completely functional.

I didn't know that we needed an update for the display, since I have never turned them on. Do we also need a password to access certain settings???

From your post, it sounds like they still are not going to provide me with a file that I can use to update the firmware that it is only done remotely.

However, I seem to remember that someone posted in this thread that they received a file to update their firmware. Unfortunately, there are over a 1000 posts in this thread, so finding a single post will be difficult. I will save this search as a last resort should I not be able to get a firmware update when I need it.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 7

- Views

- 504

- Replies

- 54

- Views

- 2K