ianganderton

Auckland, NZ

Evening from a locked-down New Zealand.

We travelled from Sydney just before the lockdown started and had to self isolate for 14 days, we did that in my sister-in-law's campervan. The problem is they have stuffed their 12V lead-acid battery by not looking after it. I'm thinking I'll sort this out for them as a thank you for letting us use the camper.

This would be my first project. I've got a camper van plan of my own so I've been reading and watching lots of stuff for a while now. This smaller project would be a great to plan and action while the crazy world is doing its thing.

The camper is used by a family of 4. It's pretty old so I don't want to invest loads, just enough to do the job.

Please bear with me, I have a lot of question and I'm excited to learn

I've been doing some calculations

Do any flaws in these calculations leap out at you?

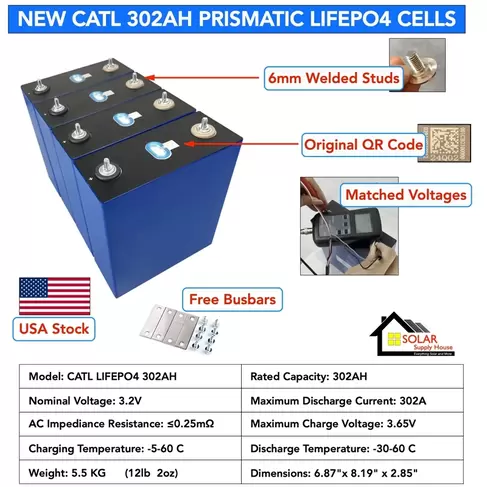

So I'm thinking 300W solar and 100Ah Lifepo4 battery

I read today that 300W panels are readily available and cost-effective because they are used so much in bigger arrays. But then I also read the series vs parallel post on Explorist.life today and that talks about the advantage of having a higher voltage created by more panels so I'm thinking 3 x 100W would be a lot more effective, is this correct?

What metrics should I be using to evaluate the quality of a panel? e.g. THIS ONE

I want to build a simple and robust system for my in-laws. What's the best way to get recommendations on products to use?

LifePo4 Calb style cells

BMS

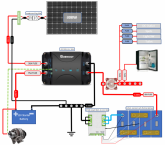

MPPT Solar Controler

240V Charger

Battery & power monitors

I really want this to be as much about the learning for me so I'm also interested in measuring devices so I can really understand what is going on

Also, what do people use to create these neat wiring diagrams I see everywhere?

All help gratefully received, thanks

Ian

We travelled from Sydney just before the lockdown started and had to self isolate for 14 days, we did that in my sister-in-law's campervan. The problem is they have stuffed their 12V lead-acid battery by not looking after it. I'm thinking I'll sort this out for them as a thank you for letting us use the camper.

This would be my first project. I've got a camper van plan of my own so I've been reading and watching lots of stuff for a while now. This smaller project would be a great to plan and action while the crazy world is doing its thing.

The camper is used by a family of 4. It's pretty old so I don't want to invest loads, just enough to do the job.

Please bear with me, I have a lot of question and I'm excited to learn

I've been doing some calculations

Do any flaws in these calculations leap out at you?

So I'm thinking 300W solar and 100Ah Lifepo4 battery

I read today that 300W panels are readily available and cost-effective because they are used so much in bigger arrays. But then I also read the series vs parallel post on Explorist.life today and that talks about the advantage of having a higher voltage created by more panels so I'm thinking 3 x 100W would be a lot more effective, is this correct?

What metrics should I be using to evaluate the quality of a panel? e.g. THIS ONE

I want to build a simple and robust system for my in-laws. What's the best way to get recommendations on products to use?

LifePo4 Calb style cells

BMS

MPPT Solar Controler

240V Charger

Battery & power monitors

I really want this to be as much about the learning for me so I'm also interested in measuring devices so I can really understand what is going on

Also, what do people use to create these neat wiring diagrams I see everywhere?

All help gratefully received, thanks

Ian