Do I need to connect each panel individually to the ground, or can I just connect the ground to the end of the metallic mount that all panels are attached to?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Not grounding panels

- Thread starter Siamac

- Start date

Look for something like an SWH grounding lug. You simply drill the self tapping green colored ground screw into each frame of the aluminum solar panel (a lot of panels have the ground point symbol on the frame or a suitable hole) and then you run and screw down the bare copper ground wire from one panels to the next. You can terminate one end at the ground rod and the other at your combiner box OR DC disconnect switch, and then run it from the ground buss bar in a conduit to where your inverter, batteries, etc are grounded.

AS AN ALTERNATIVE, SOME SOLAR PANELS OR SOLAR RAILS OR CLAMPS TO THE RAILS ARE DESIGNED TO MAKE GROUND CONTACT FOR THE PANELS, RAILS AND ARRAY METAL FRAME. ATTACHING THE PANEL TO THE RAIL GROUNDS THE PANEL AT THAT TIME. THEN CONNECT YOUR GROUND WIRE TO A GROUND ROD AND SO FORTH. NO WIRE IS NEEDED TO GO ACROSS EACH PANEL.

AS AN ALTERNATIVE, SOME SOLAR PANELS OR SOLAR RAILS OR CLAMPS TO THE RAILS ARE DESIGNED TO MAKE GROUND CONTACT FOR THE PANELS, RAILS AND ARRAY METAL FRAME. ATTACHING THE PANEL TO THE RAIL GROUNDS THE PANEL AT THAT TIME. THEN CONNECT YOUR GROUND WIRE TO A GROUND ROD AND SO FORTH. NO WIRE IS NEEDED TO GO ACROSS EACH PANEL.

Is this one that I don't need to ground individually?Look for something like an SWH grounding lug. You simply drill the self tapping green colored ground screw into each frame of the aluminum solar panel (a lot of panels have the ground point symbol on the frame or a suitable hole) and then you run and screw down the bare copper ground wire from one panels to the next. You can terminate one end at the ground rod and the other at your combiner box OR DC disconnect switch, and then run it from the ground buss bar in a conduit to where your inverter, batteries, etc are grounded.

AS AN ALTERNATIVE, SOME SOLAR PANELS OR SOLAR RAILS OR CLAMPS TO THE RAILS ARE DESIGNED TO MAKE GROUND CONTACT FOR THE PANELS, RAILS AND ARRAY METAL FRAME. ATTACHING THE PANEL TO THE RAIL GROUNDS THE PANEL AT THAT TIME. THEN CONNECT YOUR GROUND WIRE TO A GROUND ROD AND SO FORTH. NO WIRE IS NEEDED TO GO ACROSS EACH PANEL.

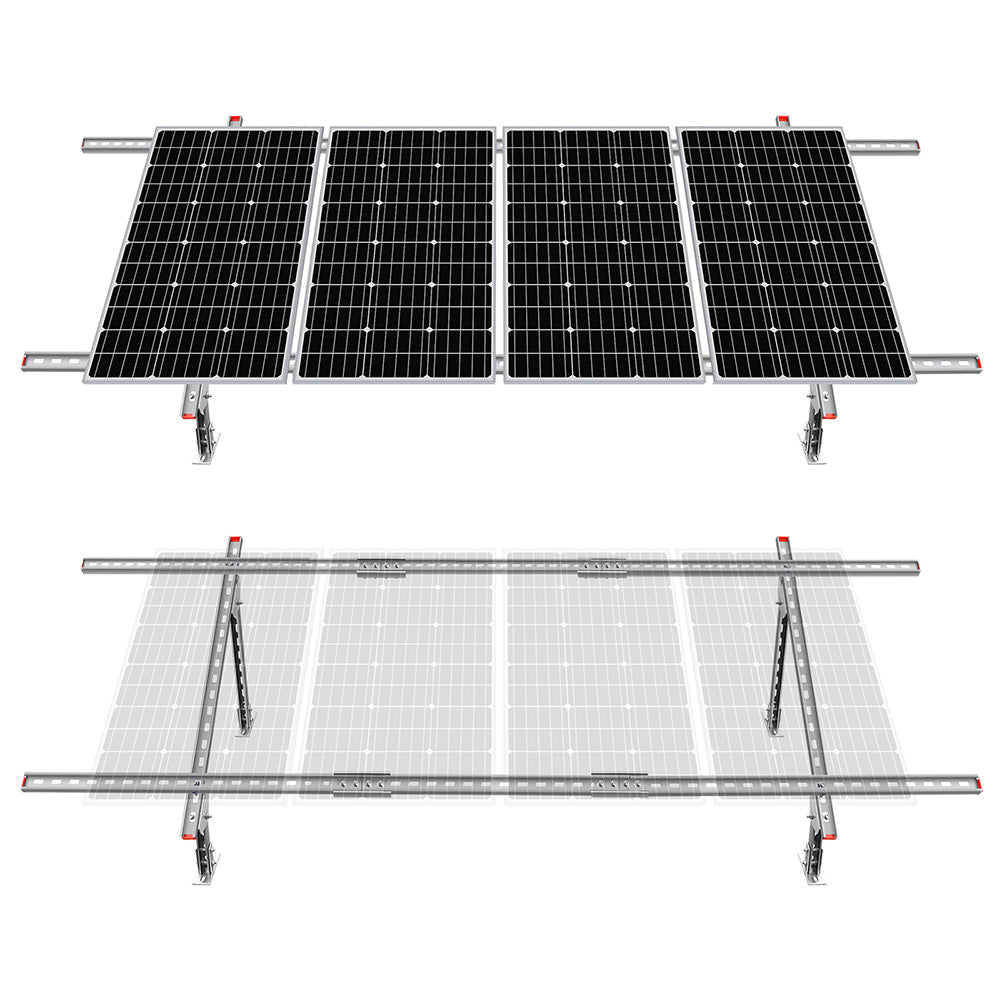

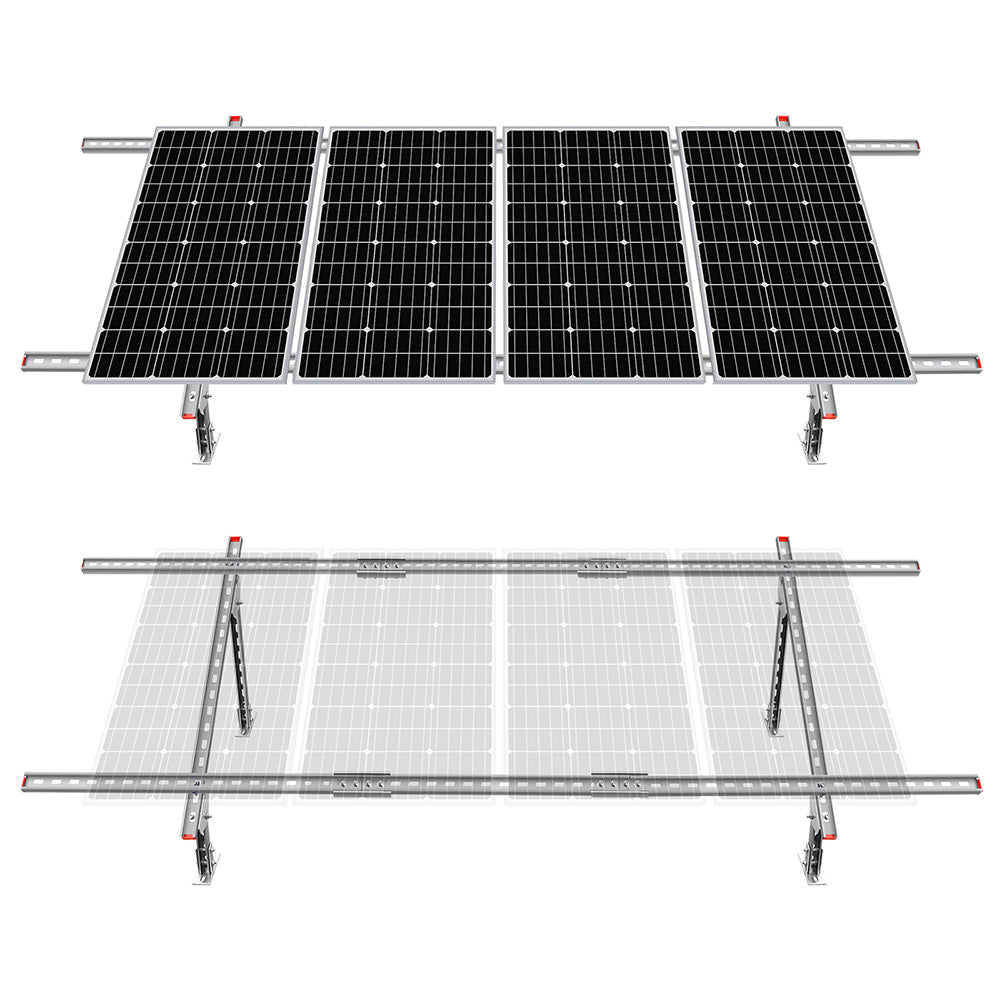

Adjustable Multi-Piece Solar Panel Mounting Brackets for 1-4 Pieces of Solar Panels | ECO-WORTHY

ECO-WORTHY Adjustable Multi-Piece Solar Panel Mounting Brackets has the capability to fit 1-4 pieces of different size ECO-WORTHY panels or other brands standard panels. It's ideal for larger installations, such as ground, flat roof, cabins and backyard sheds. Anywhere roof mounting is not a...

www.eco-worthy.com

www.eco-worthy.com

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,483

Anyone have a link to that?

(both the grounding options and Will getting shocked)

120V on the PV line?? Discussion of Will's video

@Will Prowse just did a video warning folks about 120V showing up on the PV lines. There have been several threads where people reported seeing voltage on the PV out. I always thought it was failed units, but Will reports it is normal on a lot of units. I can kinda understand if the 120V...

120V on the PV line?? Discussion of Will's video

Even Will admits that there wasn't any consistancy between all the units he tested. It looks like you scored a good one. Good to have more checks posted! ? True. But the inconsistency makes it more scary than if they were all doing the same thing. On the other hand, I can't see that I would...

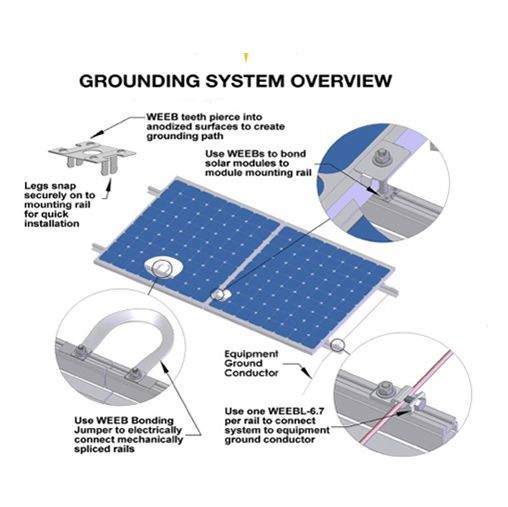

Bonding and Grounding PV Systems

Using the WEEB solution for grounding in solar applications?

A brief introduction to the WEEB grounding and bonding products.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,483

Is this one that I don't need to ground individually?

Adjustable Multi-Piece Solar Panel Mounting Brackets for 1-4 Pieces of Solar Panels | ECO-WORTHY

ECO-WORTHY Adjustable Multi-Piece Solar Panel Mounting Brackets has the capability to fit 1-4 pieces of different size ECO-WORTHY panels or other brands standard panels. It's ideal for larger installations, such as ground, flat roof, cabins and backyard sheds. Anywhere roof mounting is not a...www.eco-worthy.com

No such indication in the listing.

Add bonding for ground wire to taste.

Can I DIY convert it?No such indication in the listing.

Add bonding for ground wire to taste.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,483

It is probably a mechanically sound mount.

Looks like Unistrut (or similar brand), which you can buy at home improvement stores.

Some are hot-dip galvanized, most are thin plate of something. Make sure bolts and slot nuts work smoothly. There is also aluminum and stainless hardware.

Good materials probably more expensive than purpose-fabricated PV mounting hardware from Unirac or Iron Ridge.

As for grounding, of course you can add a UL listed grounding mechanism such as lay-in lugs. They need toothed washer to bite through aluminum oxide or anodization.

Looks like Unistrut (or similar brand), which you can buy at home improvement stores.

Some are hot-dip galvanized, most are thin plate of something. Make sure bolts and slot nuts work smoothly. There is also aluminum and stainless hardware.

Good materials probably more expensive than purpose-fabricated PV mounting hardware from Unirac or Iron Ridge.

As for grounding, of course you can add a UL listed grounding mechanism such as lay-in lugs. They need toothed washer to bite through aluminum oxide or anodization.

Checkthisout

Solar Wizard

- Joined

- Nov 14, 2021

- Messages

- 5,052

Takes less than 2 minutes a panel to install the lug and grounding wire.

Do you have a link?Takes less than 2 minutes a panel to install the lug and grounding wire.

@Will Prowse should make a easiest grounding video

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,483

registered-bum

New Member

Is there a standard protocol for connecting a 6awg bare copper ground wire to an aluminum PV panel or aluminum supporting frame?

Any corrosion or galvanic action to worry about, preference for special stainless steel fasteners?

Any corrosion or galvanic action to worry about, preference for special stainless steel fasteners?

Grounding panels has nothing to do with lightning.

You need to run an EGC from the panels so the panels are bonded to the system ground.

The purpose is so that any AC power that could energize metal surfaces will have a path for ground fault clearing.

Do not install a ground rod at the array location. It is not needed and can lead to a gradient pulse across your electrical system. A direct lightning strike on an array will cause damage, there is no way to prevent it. Watch Mike Holt's video shown in this post.

He seems to be saying you should have only one ground rod per house, if I understand correctly.

So can I ground/bond my DIY system with my professionally installed and grounded rooftop solar system? (they're connected to different subpanels but ultimately go to the same main panel)

BryceFreeman

Ecoworthy Distributor

Thank you...that was what an engineer told me...maybe something's wrong ? I'll read the other posts in this thread and learn more.Not true. Some inverters float the panels at very high voltages with respect to ground. An unlucky person who touched a faulty panel frame or rack could have a nasty surprise/early death. This is why proper earthing of mounting systems is considered mandatory by practically all panel, racking and inverter vendors.

Zwy

Emperor Of Solar

Everything metal that can become energized with electricity needs to be bonded to the grounding system. The grounding system should only have one grounding location. It might be comprised of more than one rod depending on soil conditions, for example poor soil conductivity may require a pair of rods 6 feet apart bonded to together to increase earth contact.He seems to be saying you should have only one ground rod per house, if I understand correctly.

So can I ground/bond my DIY system with my professionally installed and grounded rooftop solar system? (they're connected to different subpanels but ultimately go to the same main panel)

As for running a ground wire from one array to another, then to main panel,, you most certainly can if the AHJ does not have any requirements stating to the contrary.

Zwy

Emperor Of Solar

I think you are referring to using an auxillary ground rod at the array, which is not required. It is allowed, but bonding still needs to be run to the main panel for grounding purposes as required by NEC.Actually, the video clearly explains why array grounding is NOT required.

Zwy

Emperor Of Solar

So can I tie the ground wire at my main panel instead of the subpanel that the PV cables are going to? (where the inverter is)

My main panel is much closer than the subpanel.

Yes, as long as all metal in a system is bonded together.

Exposed and not protected requires 6AWG solid. Once inside a cabinet or conduit, it can be smaller. I run 10AWG from array junction box to my house inside underground conduit.And is 8 AWG copper big enough as ground? Does it need to be covered?

Zwy

Emperor Of Solar

Minimum risk as the array is bonded to the system ground.Isn't this a risk no matter what?

It does carry some risk with a nearby lightning strike.

Similar threads

- Replies

- 8

- Views

- 350

- Replies

- 36

- Views

- 805

- Replies

- 17

- Views

- 352

- Replies

- 0

- Views

- 81