This is my first time posting to this forum but I’ve used it several times as a resource. I want to make sure I have this system planned out correctly before I purchase all of the equipment. I have never installed a solar system of this size before and I’m going to try my best to include all of the necessary information in this post. Any help is appreciated.

I'm in the process of building an off-grid home and over the next two months (Dec-Jan 2024) I will be ordering all of the components and putting together this system (I currently own the 250W panels). The house construction finishes in mid spring (2024) so I need to have the system completed by then and ready for county inspection.

I am responsible for wiring up the solar equipment and a licensed electrician will be handling running the AC power from the inverter to the main panel, an AC disconnect, and wiring up receptacles, lights, etc.

Site: Northern Midwest

System type: Full off-grid solar power

Mount: Galvanized steel ground mount

Distance: PV array is roughly 150’ from house

Inverter/Bat Location: Inverter and battery are located inside the house

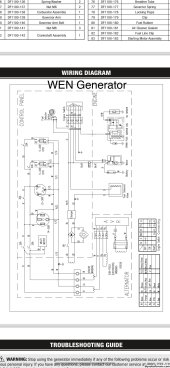

Backup Power Source: WEN 11kW Dual Fuel Generator

Inspections: local county inspection

Equipment:

•EG4 18kPV w/2x PowerPro 14.3kWh batteries

•Watts247 4-2 combiner box

•18 used 240W SanTan panels

•24 new 365W Hyundai panels

•10AWG direct burial cable

Panels (I’m going to gloss over the series-parallel connections because I don’t have concern about this portion of the build):

Used 240W: VOC 37.2

New 365W: VOC 40.8

The panels will be wired up in series into 4 strings. Two strings consisting of 240W panels and two consisting of 365W panels. That will run into the combiner box to parallel those two like strings together.

Combiner box output will have two strings at about 350VDV (240W panels) and about 500VDC (365W panels).

Direct Burial Wire: (I have no plans to run conduit).

I’m using UL 4703 10AWG direct burial rated PV cable to run the power from the combiner box 150’ to the house where the 18kPV and batteries are located.

I haven’t been able to find specifics on how many cables I can bury in the same trench or spacing requirements or anything like that. I did get confirmation from the county that the trench needs to have 24” of soil on top of cables and schedule 80 PVC at ground entry and exit points at least 18” into the ground.

I will likely contact the county again to ask those questions but the plan as of now is to run 6 cables in the same trench, a positive and negative for each of the two strings and an extra set of two cables so I can add a third string of panels later on (since the 18kPV has three MPPT’s). Then surround the cables in a layer of sand before backfilling the trench to protect from sharp rocks, etc. I will be installing that magnetic marking tape in the ground to mark the wire location for future reference.

Grounding/Earthing:

The plan is to connect all of the aluminum PV frames to each other and to the galvanized steel ground mount and run that to an 8’ grounding rod located at the PV array. And also run the combiner box ground wire to this same grounding rod? (This I am unsure of.)

Everything else that needs grounding at the house (18kPV, 2 batteries, etc) will be connected to the grounding rod the electrician will install to ground the main panel.

Things I’m unsure of:

I'm in the process of building an off-grid home and over the next two months (Dec-Jan 2024) I will be ordering all of the components and putting together this system (I currently own the 250W panels). The house construction finishes in mid spring (2024) so I need to have the system completed by then and ready for county inspection.

I am responsible for wiring up the solar equipment and a licensed electrician will be handling running the AC power from the inverter to the main panel, an AC disconnect, and wiring up receptacles, lights, etc.

Site: Northern Midwest

System type: Full off-grid solar power

Mount: Galvanized steel ground mount

Distance: PV array is roughly 150’ from house

Inverter/Bat Location: Inverter and battery are located inside the house

Backup Power Source: WEN 11kW Dual Fuel Generator

Inspections: local county inspection

Equipment:

•EG4 18kPV w/2x PowerPro 14.3kWh batteries

•Watts247 4-2 combiner box

•18 used 240W SanTan panels

•24 new 365W Hyundai panels

•10AWG direct burial cable

Panels (I’m going to gloss over the series-parallel connections because I don’t have concern about this portion of the build):

Used 240W: VOC 37.2

New 365W: VOC 40.8

The panels will be wired up in series into 4 strings. Two strings consisting of 240W panels and two consisting of 365W panels. That will run into the combiner box to parallel those two like strings together.

Combiner box output will have two strings at about 350VDV (240W panels) and about 500VDC (365W panels).

Direct Burial Wire: (I have no plans to run conduit).

I’m using UL 4703 10AWG direct burial rated PV cable to run the power from the combiner box 150’ to the house where the 18kPV and batteries are located.

I haven’t been able to find specifics on how many cables I can bury in the same trench or spacing requirements or anything like that. I did get confirmation from the county that the trench needs to have 24” of soil on top of cables and schedule 80 PVC at ground entry and exit points at least 18” into the ground.

I will likely contact the county again to ask those questions but the plan as of now is to run 6 cables in the same trench, a positive and negative for each of the two strings and an extra set of two cables so I can add a third string of panels later on (since the 18kPV has three MPPT’s). Then surround the cables in a layer of sand before backfilling the trench to protect from sharp rocks, etc. I will be installing that magnetic marking tape in the ground to mark the wire location for future reference.

Grounding/Earthing:

The plan is to connect all of the aluminum PV frames to each other and to the galvanized steel ground mount and run that to an 8’ grounding rod located at the PV array. And also run the combiner box ground wire to this same grounding rod? (This I am unsure of.)

Everything else that needs grounding at the house (18kPV, 2 batteries, etc) will be connected to the grounding rod the electrician will install to ground the main panel.

Things I’m unsure of:

- Best way to get generator power ran to the inverter.

- Dry contact hookup to signal and auto start generator based on inverter criteria input. (This generator has an electric start with a key and I have attach the wiring diagram.) What is a good aftermarket controller that would best accomplish this?

- Does the solar array grounding rod need connected to the grounding rod at the house? If so, does running a ground cable in the trench with the DC power cables from one grounding rod to the other satisfy that?

- Are there any issues burying 6 - 10AWG UL 4703 direct burial rated cables together in the same 24” trench?