I have the 2000w version of the inverter, it is fine. The built in charger is a plus if you want to use it in UPS mode. But for that price you can get victron or other LF inverter.

You can get much better prices on the batteries than that.

You can get much better panels with higher voltage/wattage/efficiency.

Basically I am saying build your own system from scratch verse what you can get on amazon. It isn't hard and unlike the plug and play kit you can troubleshoot it because you understand how it is put together. There are many build on here from people adding power to a shed.

Here is a similar one to review.

Alright I'm a decent fellow. But I'm not good at everything. Well, I suck at solar power. This is my third attempt to build a solar power for my cabin. My first two attempts busted and I couldn't figure out how to fix it. I figure after these two attempts and the subsequent attempts at repair...

diysolarforum.com

And, building yourself verse plug-n-play you can generally save 1/2 or so off the cost and it will be right-sized for your use and better quality.

First step - an energy audit - list all devices and their wattage and if they are inductive *power tools* And figure out how many will be running at once. Then figure out how long you want them to run.

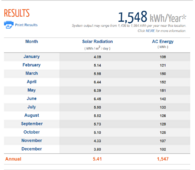

This will give you required inverter size and battery size. From that you can figure required solar panel size - my rough estimate is 5x the battery size. That will give you how many panels and what voltage/current you need from a MPPT to recharge the batteries in 5 hours.

You will want a LF inverter that is rated for a good duration of surge capacity when you start power tools. The HF have only a few seconds at most of surge capacity to double the rated wattage. The LF will typically have a 3x surge capacity for 30 seconds or more.

Once you have the inverter size you can just read in the manual about required wire and fuses or it can be figured very easy.

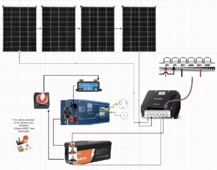

This is my UPS system - I do have a different MPPT than the one shown, but the one shown is not in any way bad.

The drawing was made in drawio in about 10 minutes - you can watch a youtub video to learn basics in about 15 minutes.

For you, you will want to replace the battery with multiple and the inverter with one that suits you.

Doesn't matter if it is DIY or kit form, you will end up bolting together.