Try shutting off breakers one by one while observing that 7 volt N-G voltage. Also you could try measuring N-G resistance at that 7 volt point but only after de-energizing the whole house and solar system. It could reveal loose or corroded connection.

Been there, done that.

I've spent enough time trying to prove it was something other than the inverters. Since the first week of March. Have the rabbit hole badge to prove it.

It is the 6500EX inverters. It all clicked for me eventually.

Didn't you say that's because 6548's have N-G bonding screw installed? Have you tried removing it?

You need N-G bond, the LV6548 switches neutral.

The 6500EX does not switch neutral with the firmware update SS pushes for correcting their problem.

I had a slight flicker when first turning the system on under a light load. It was very slight. I should have stopped there.

Next, attempted the mobile firmware with one bonding screw in the inverters, flicker was about the same.

Next, removed bonding screw and updated to stationary firmware, that is when you get this.

This when I found the 7V on N to G during the flicker. Change the load and the 7V is gone.

Next, inverters were RMA'd. Installed the LV6548's during the 3 weeks it took SS to send replacements. LV6548's worked perfect, I changed only the inverters and the PV input VOC was reduced to under 250V.

Replacements did the same, bad flicker. Noticed noise on L to G on scope.

Next, inverter firmware updated to 79.70, still bad flicker. Noticed noise on L to G is still there. L to N is clean.

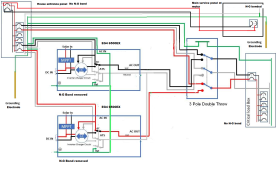

Went looking for ground issue, added N-G bond at loads panel. Flicker did not appear until evening, it was slight, load was around 800W, noted fridge and freezer running. Decided to do some checking, found the inverter output voltage fluctuating. Removed N-G bond at loads panel. Turned off the light, noticed light glowing with switch turned off. Not good, indicates backfeed on N.

Flipped back to grid using 3 pole transfer switch. Shut down system.