BlueMarblePA

Solar Enthusiast

What is the best distance between the roof rack rails?

In this video, he says you have to measure a distance between the holes in the solar panel, and use that distance in order to space apart the rails on the roof. I am confused by this, because the way that the solar panels are clamped on to the rails does not seem to require you to utilize the holes? It simply clamps on to the edge itself.

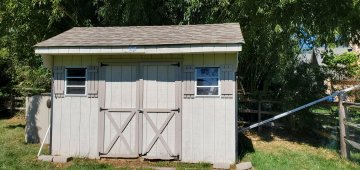

I would imagine it doesn't really matter. For example, i am using LG panels which are 64 inch tall, and my roof shed is about 60 inch. I was just going to put the rails 12 inch from the bottom and 12 inch from the top of the shed roof which would result in a rough distance of 36 inch between the two rails.

Minute 1:20 of the video

In this video, he says you have to measure a distance between the holes in the solar panel, and use that distance in order to space apart the rails on the roof. I am confused by this, because the way that the solar panels are clamped on to the rails does not seem to require you to utilize the holes? It simply clamps on to the edge itself.

I would imagine it doesn't really matter. For example, i am using LG panels which are 64 inch tall, and my roof shed is about 60 inch. I was just going to put the rails 12 inch from the bottom and 12 inch from the top of the shed roof which would result in a rough distance of 36 inch between the two rails.

Minute 1:20 of the video