Schneider tech support is not very good. (being nice)

Going by the battery specs you posted back at the beginning of this thread, here is what I would suggest...

Custom

2 stage no float

Bulk/Boost Voltage Set Point 28.4 volts (this is 3.55 volts per cell, which is still 99% full on LFP)

Absorption Time 3,600 seconds (1 hour seems plenty on Lithium cells)

Absorption Voltage Set Point 28.4 volts

Float Voltage Set Point 26.4 volts (The cells should not settle this low, 3.3 volts per cell) Float is turned off anyways.

Bulk Termination Voltage What is the limit? 28.0 volts would be good, but it probably won't go that high

Bulk Termination Time Mine is set to just 10 seconds. When the cells reach full voltage, we want to reduce the current fairly quick.

Absorption Period Timeout 60 minutes (1 hour again, seems good, mine is typically done in 20 minutes)

For the battery monitor, try these settings

f1.0 Charger Float Voltage 27.2 volts (that is 3.4 per cell which is where LFP cells tend to rest after a charge)

f1.1 Charger Float Current Try 10% The current has to fall below this value for the battery monitor to sync. 10% of 170 Amp Hours is 17 amps.

f1.2 Auto Sync Time The default if 4 minutes, try dropping it to 60 seconds, 1 minute to see if that helps it sync up.

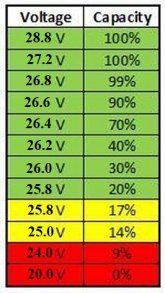

f1.3 Discharge Floor How low do you want to run your batteries? 50% for lead acid is normal, with LFP you can safely go down to 20%

f1.4 Battery Temperature Set this to the temperature where the battery is. It has basically no effect on lithium cells

f1.5 Time Remaining Averaging Filter As loads change it calculate how long you have until the battery runs out. How fast do you want this

to move? It only has 3 settings, 1 is the middle, 0 faster, 2 slower

f1.6 Auto-Sync Sensitivity Default is 5, going lower will more likely trigger an auto sync, higher will make it take longer to auto sync.

f2.0 Battery Capacity The logical choice is 170 Amp Hours, but you might need to lower it a bit to get accurate readings.

f2.1 Nominal Discharge Rate At what rate are your cells spec'd? 20 hour is normal for lead acid, with LFP, 5 hour is probably closer.

f2.2 Nominal Temperature +20C is probably good, but does not matter much, this is for temp compensation, and LFP zero comp

f2.3 Temperature Coefficient Set this very low or even off. LFP cells don't lose capacity as long as they stay above freezing.

f2.4 Peukert's Exponent 1 is normal for LFP, but we might get slightly more accurate readings at high loads with a slight increase here.

I have found people recommending 1.01 to 1.03 on good cells. The higher the current draw, you do lose a little capacity

f2.5 Self Discharge Rate This only matters if the system sits with no load. How much does it lose per month. Off or a small number for LFP

f2.6 Charge Efficiency Factor My cells measured 98% This is how many Amp Hours you get out, for each Amp Hour charged in.

Hopefully that should work for you.