Frank in Thailand

making mistakes so you don't have to...

Does anyone know:

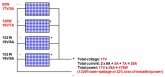

I used to have 3 sets of 9 panels, each connected to "own" MPPT inverter.

Together they are connected to the same battery pack by "back bone"

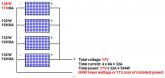

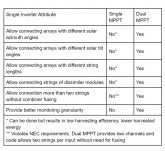

Is there a reason not to make the 3 x 9 panels to one "solar back-bone"?

I understand that it a few panels are partly shaded (by cloud or so) their voltage drops.

Having 9 in a series, I already have this "problem" (now 335v, can do max 450v)

and even if it happens, i have lower voltage, but still higher amps.

Watts are watts.

they don't just get lost, right?

If one set of the 9 suddenly have 100 watts per panel and lower voltage, it doesn't stop the other 18 for giving 275 watts at high voltage

total voltage will be little lower.

That's where the MPPT does its work

I have enough left over 4-AWG copper cable (+ 80 meters) to make a back-bone to the solar panel groups.

(they now use 10- AWG)

I need to re-do them anyway.

is it good or bad to do??

and if it is, why ??

I used to have 3 sets of 9 panels, each connected to "own" MPPT inverter.

Together they are connected to the same battery pack by "back bone"

Is there a reason not to make the 3 x 9 panels to one "solar back-bone"?

I understand that it a few panels are partly shaded (by cloud or so) their voltage drops.

Having 9 in a series, I already have this "problem" (now 335v, can do max 450v)

and even if it happens, i have lower voltage, but still higher amps.

Watts are watts.

they don't just get lost, right?

If one set of the 9 suddenly have 100 watts per panel and lower voltage, it doesn't stop the other 18 for giving 275 watts at high voltage

total voltage will be little lower.

That's where the MPPT does its work

I have enough left over 4-AWG copper cable (+ 80 meters) to make a back-bone to the solar panel groups.

(they now use 10- AWG)

I need to re-do them anyway.

is it good or bad to do??

and if it is, why ??